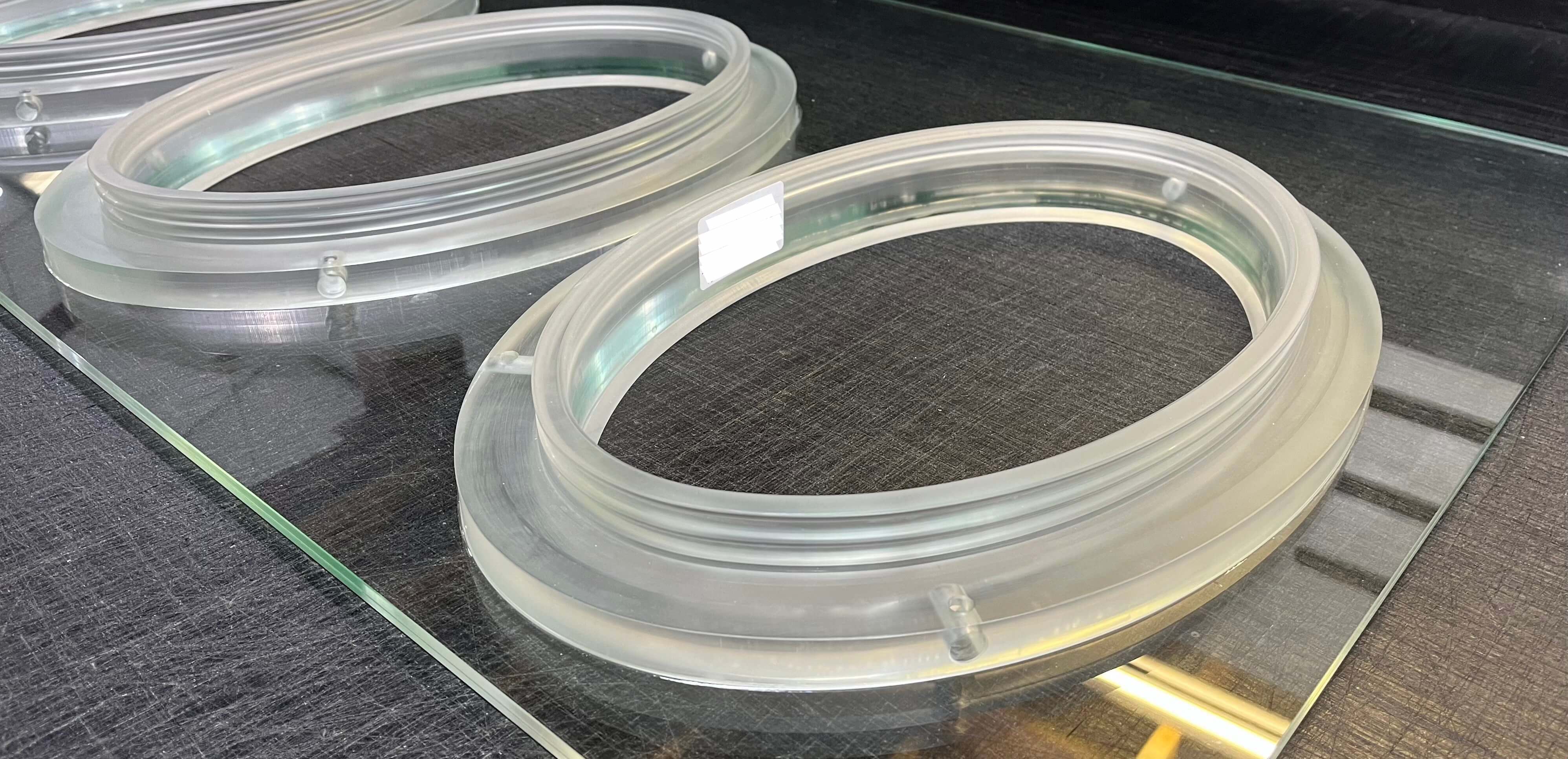

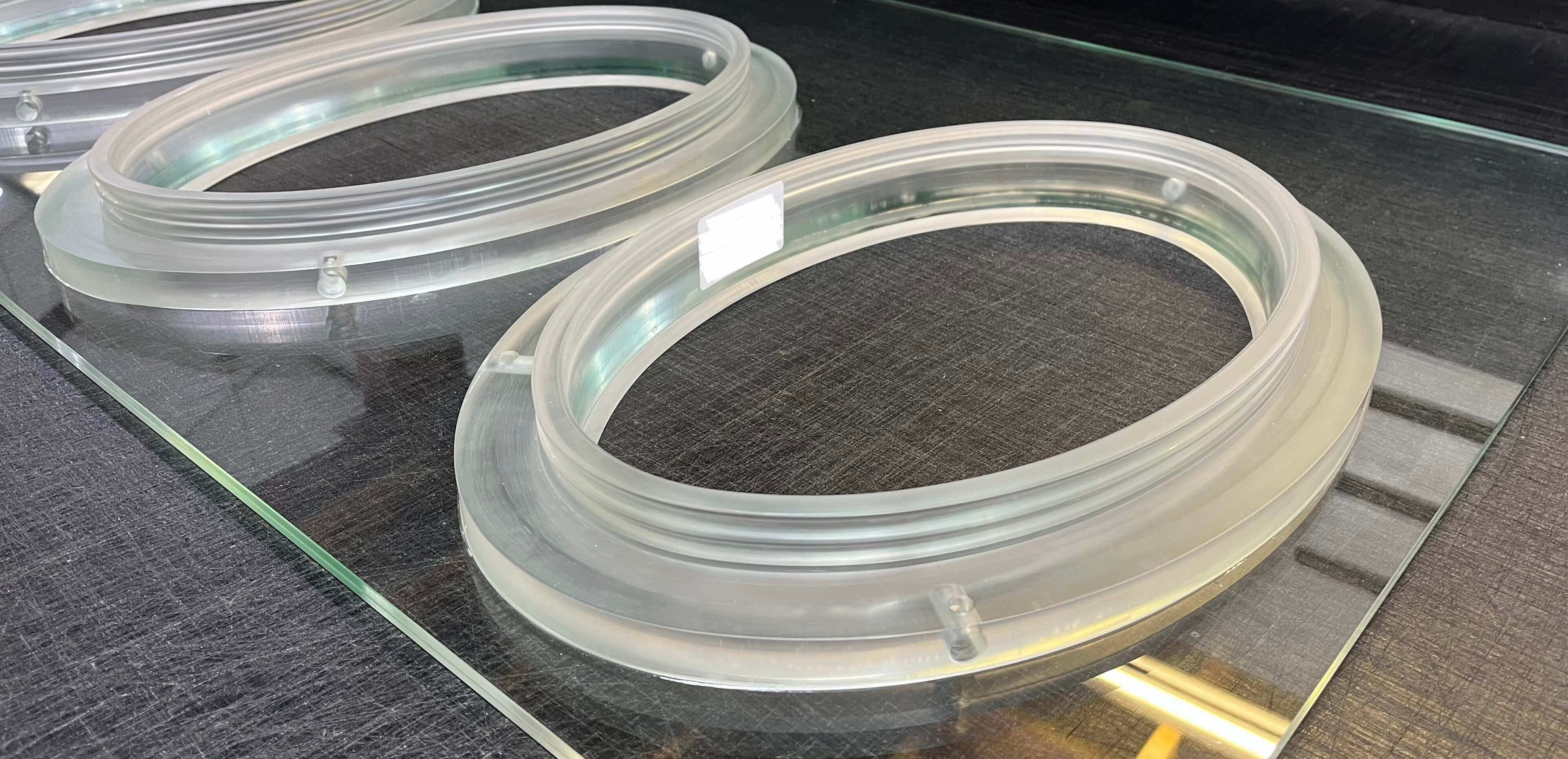

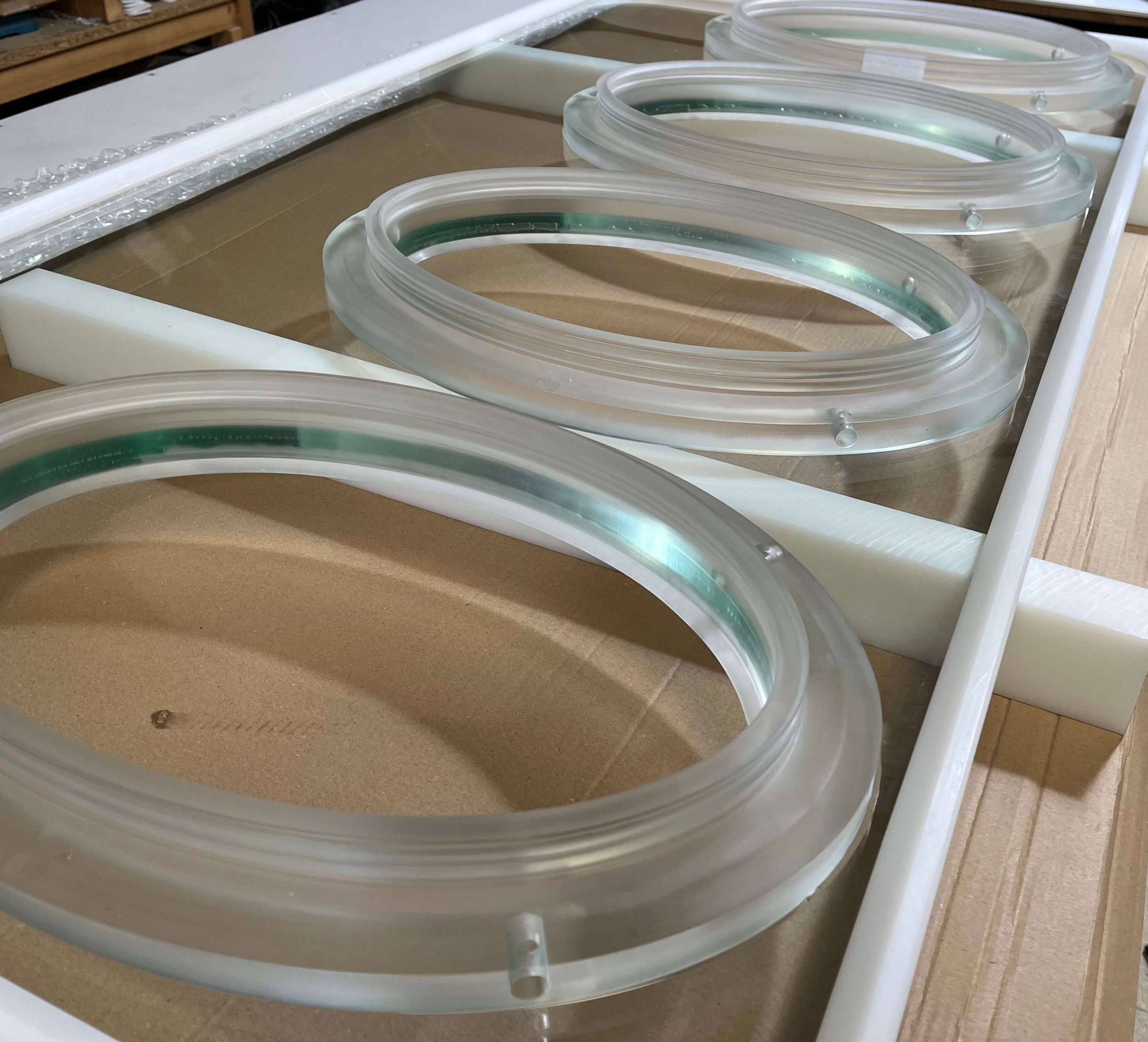

Here's an example of a Glass Four Port Visor made from Clear Cast Acrylic material manufactured by one of our engineers, Joel, earlier last week.

Just like with all projects we undertake at WKH, we customise components to match the exact needs and specifications of our client, and this Glass Four Port Visor made from Clear Cast Acrylic was no different.

What our client required

Our client required an isolator visor to be produced from toughened and laminated safety glass, providing us with drawings, instructions and what would be the final application.

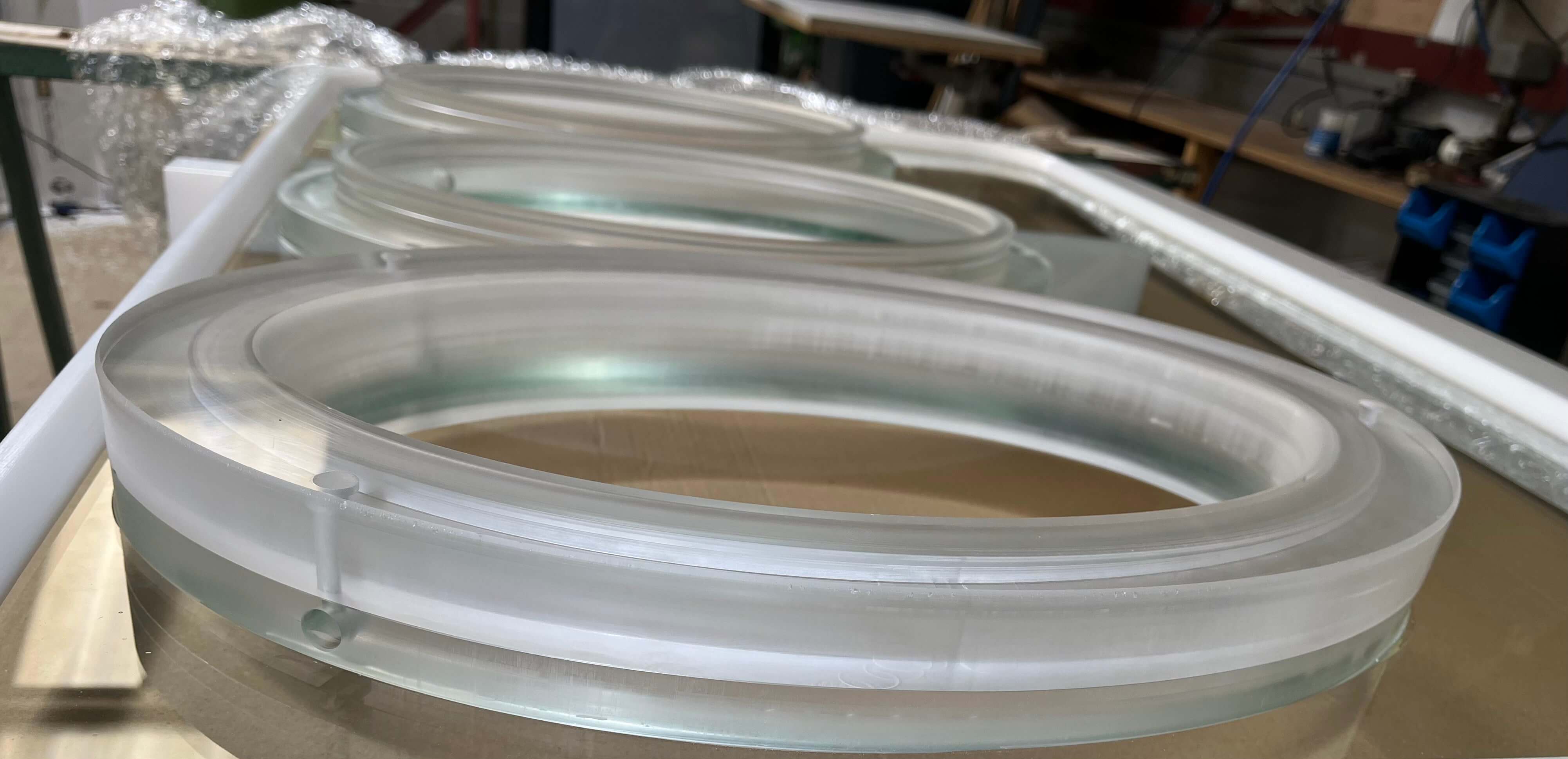

To guarantee the sheet was certified for safety we would need to make eight pieces. With four of the parts being made for the front and four of the parts being made for the back.

The pieces would be made to fit perfectly into their counterpart that would then be sealed, fused and bonded to ensure containment and maximum safety.

How we made it

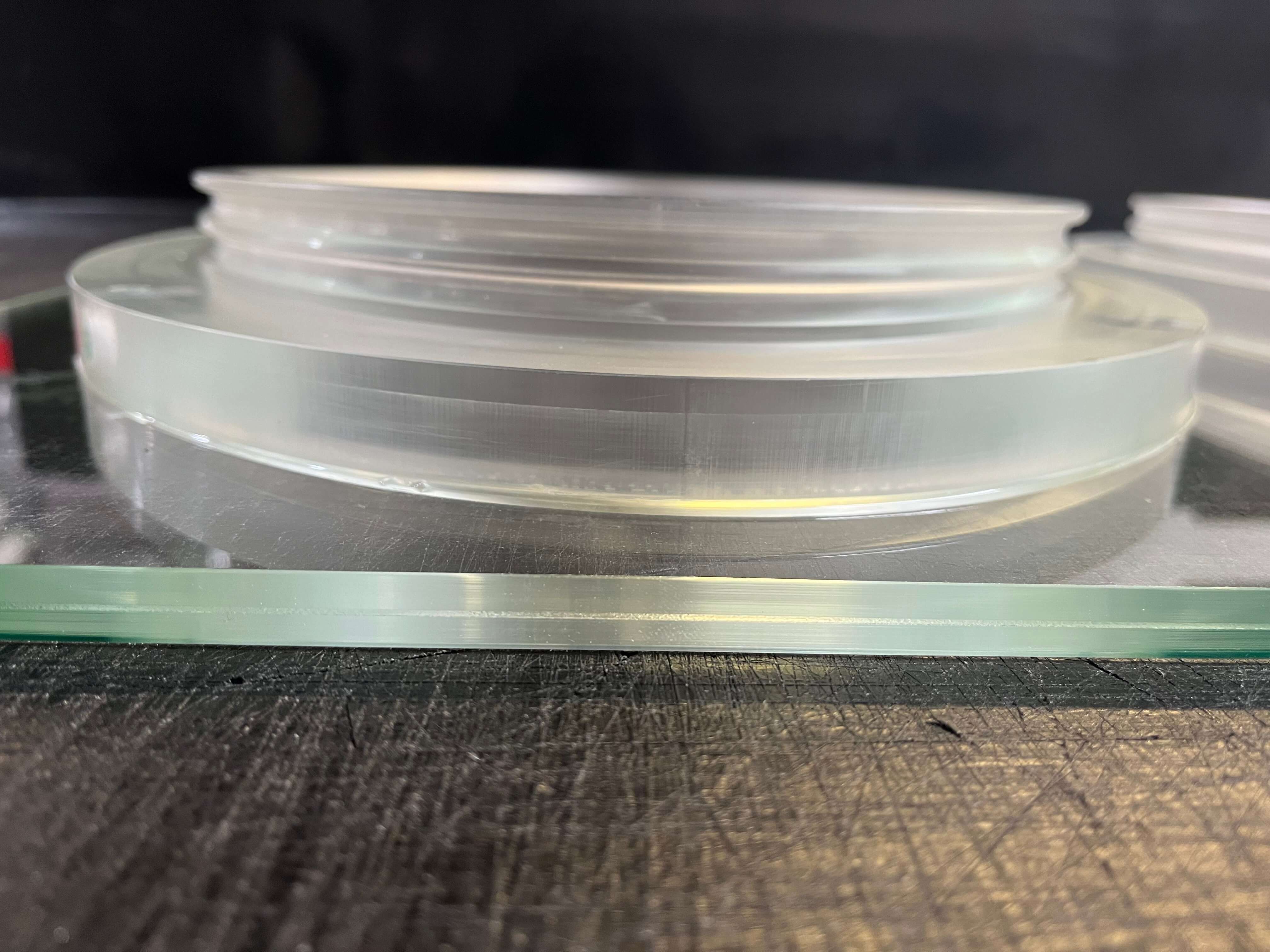

Once the glass had been cut and shaped using CNC Water Jet the Acrylic parts were machined from solid block of Clear Cast Acrylic.

Machined on a Vacuum Bed CNC Router, the oval (ellipse) shaped Glove Ports required undercuts, grooves and side holes.

Once completed we utilised specialist plastic fabrication techniques as the Acrylic Glove Ports were then bonded to the glass using a UV ( Ultra Violet ) bonding system, which fuses the Acrylic Glove Ports to the glass and is the final part in the process.

Final applications

There are a number of industries Glass Four Port Visors are made for including: Containment and Isolation Engineering, Pharmaceutical Equipment Manufacturing, Aseptic Glove Box Manufacturers, R & D Nuclear applications + testing.

This particular Glass Four Port Visor made from Clear Cast Acrylic is to be used for containment and aseptic systems.

Book your next project with WKH Group, contact us on 0113 239 1909, email us or request a quote.

Blog posts

Lexan is a brand name for a type of polycarbonate resin thermoplastic developed by General Electric Plastics (now owned by SABIC). Known for its strength, durability, and optical clarity, Lexa...

Teflon, a brand name commonly associated with the chemical compound polytetrafluoroethylene (PTFE), is a synthetic fluoropolymer of tetrafluoroethylene. First developed in the 1930s by Roy Plunket...

What is the density of High Density Polyethylene?

High-Density Polyethylene (HDPE) has a density range of 0.94 to 0.97 grams per cubic centimetre (g/cm³), which sets it apart from other types of polyethylene, such as Low-Density Polyethylene (LDP...