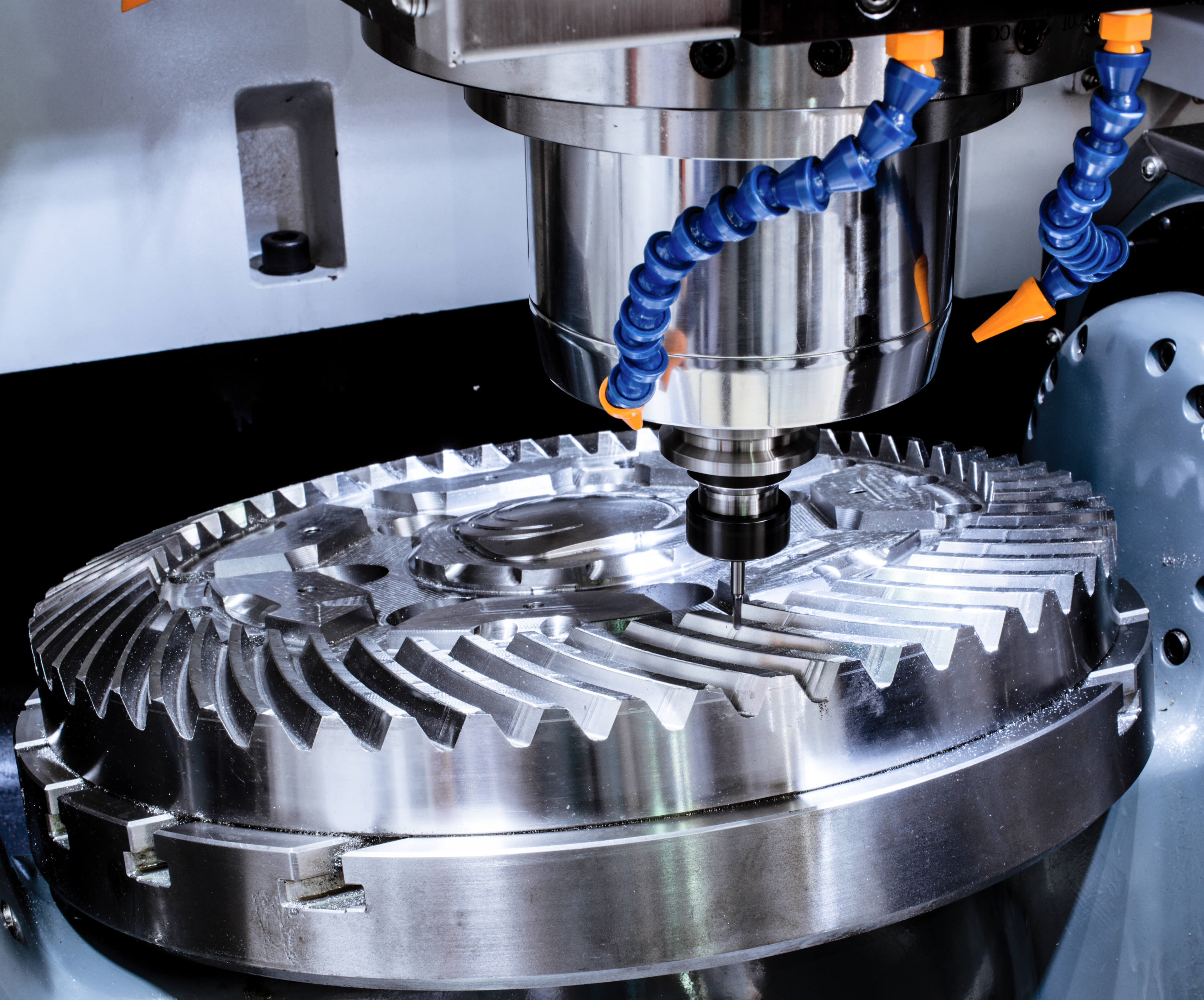

Metal Machining

We provide specialist metal machining services designed to meet the diverse needs of our clients and their respective industries.

With years of experience and state-of-the-art equipment, we can machine and engineer metal components tailored to your exact specifications, ensuring high-quality results every time.

From small, intricate and complex to larger heavier duty parts and components, we adapt to the demands and requirements of all our customers and their respective industries.

Metal Machinery We Use

To manufacture your parts, we operate a diverse range of CNC metal machines, including cutting, routing, and milling equipment.

Our machinery includes advanced models such as the Doosan DNM4500, Haas VF4SS, four Haas VF4 machines, Haas VF2, Doosan Puma GT2600, Doosan Puma GT2600M, as well as Citizen models L20 Type VII, C32 Type VIII, A32 Type VII, A20 Type VII, L20 Type VIII, and Colchester Tornado TM8.

Additionally, we utilise two Haas TL1 Tool Room Lathes. We work with a variety of materials, including aluminium, stainless steels, super duplex, and titanium, ensuring high-quality components and parts tailored to your needs.

Metal Parts and Components We Manufacture

We engineer a number of metal parts and components, including stainless steel coupling flanges, CNC turned components with threaded holes, machined metal domes, CNC machined bearing housings, and stainless steel drive shafts for automated production in the food industry, as well as complex stainless steel components for the pharmaceutical industry.

For WKH, no component, part, or project is too complex – we adapt to the demands and requirements of all our customers and their respective industries.

Why choose the WKH Group?

There are many reasons why we stand out among our competitors, however here are a few reasons why we are the perfect match for you.

Highest Quality Service.

With over thirty years experience in plastic engineering across all industries, we bring the highest level of expertise to every project we undertake.

We collaborate closely with our clients and project engineers to ensure a thorough understanding of your requirements and specifications.

On Time, Every Time.

We understand the importance of time-sensitive projects which is why we prioritise responsiveness and proactiveness in our approach.

Our team is dedicated to swiftly addressing your needs and challenges, ensuring timely delivery without compromising on quality or precision.

Innovation & Investment.

At WKH Group, we are committed to innovation and investing in the latest technology, training and machinery to ensure we always provide the best solutions to our clients.

Our dedication and commitment to striving for perfection has kept us at the forefront of our industry for today, tomorrow and for decades to come.

BSEN ISO 9001:2015 Certified.

At the WKH Group we committed to quality excellence, holding certification to BSEN ISO 9001:2015 standards.

Our dedication to maintaining the highest quality standards is reinforced by our investment in the latest technology and machinery.