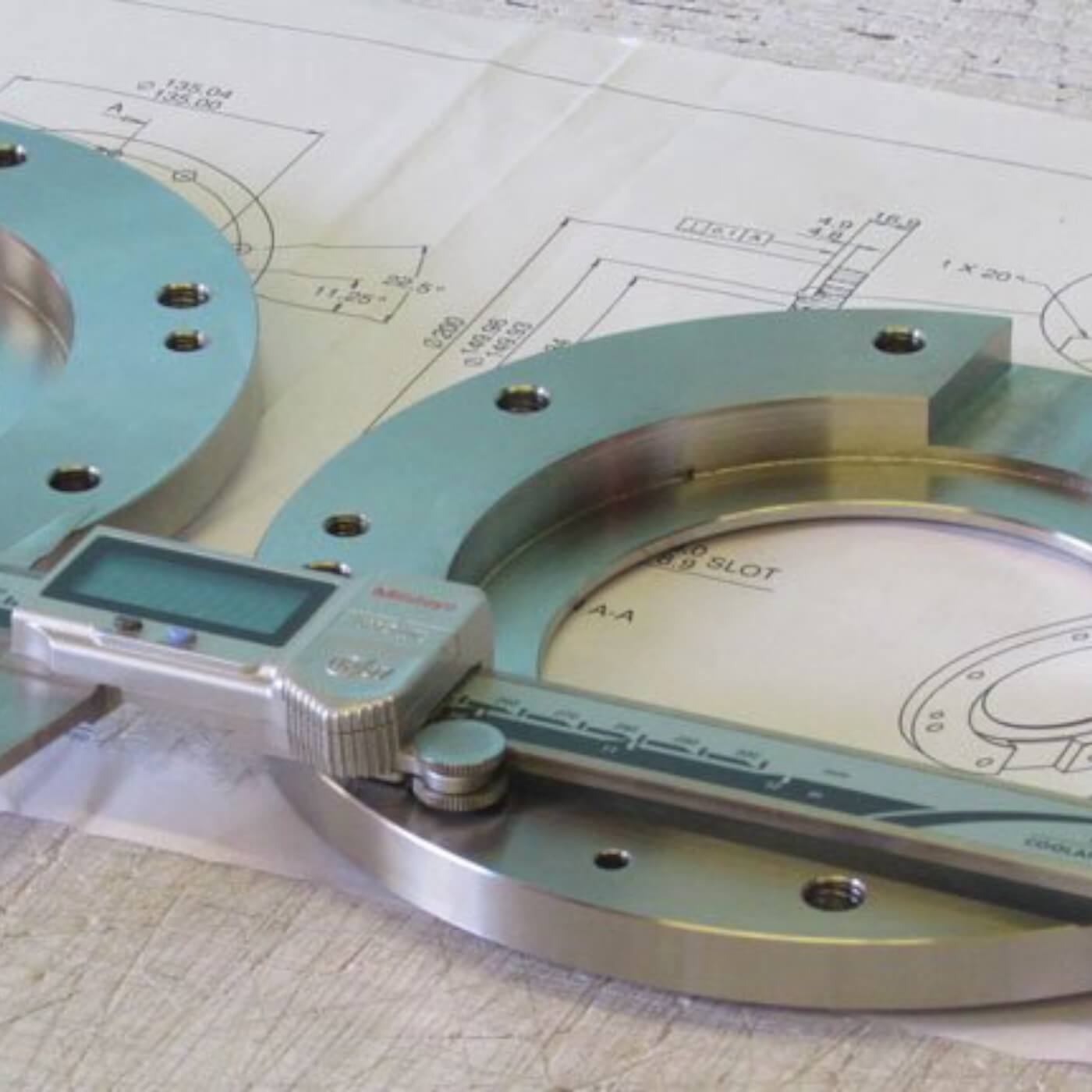

We specialise in manufacturing high-precision metal components with CNC turning, featuring threaded holes meticulously positioned on a Pitch Circle Diameter (PCD). This arrangement of threads on a PCD is essential for parts that require symmetrical alignment or mounting, ensuring they fit perfectly within larger assemblies.

Using advanced turn-mill machines with live tooling capabilities, we achieve a high level of precision and versatility in our manufacturing process. Live tooling enables us to mill, drill, and thread while turning, allowing us to create complex geometries and intricate threads without needing multiple setups. This technology, combined with the expertise of our engineers, ensures that each component meets exact specifications and maintains consistent accuracy.

Whether your project involves challenging threading requirements or intricate designs, our machinery and craftsmanship allow us to produce reliable, high-quality components tailored to your unique needs.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.