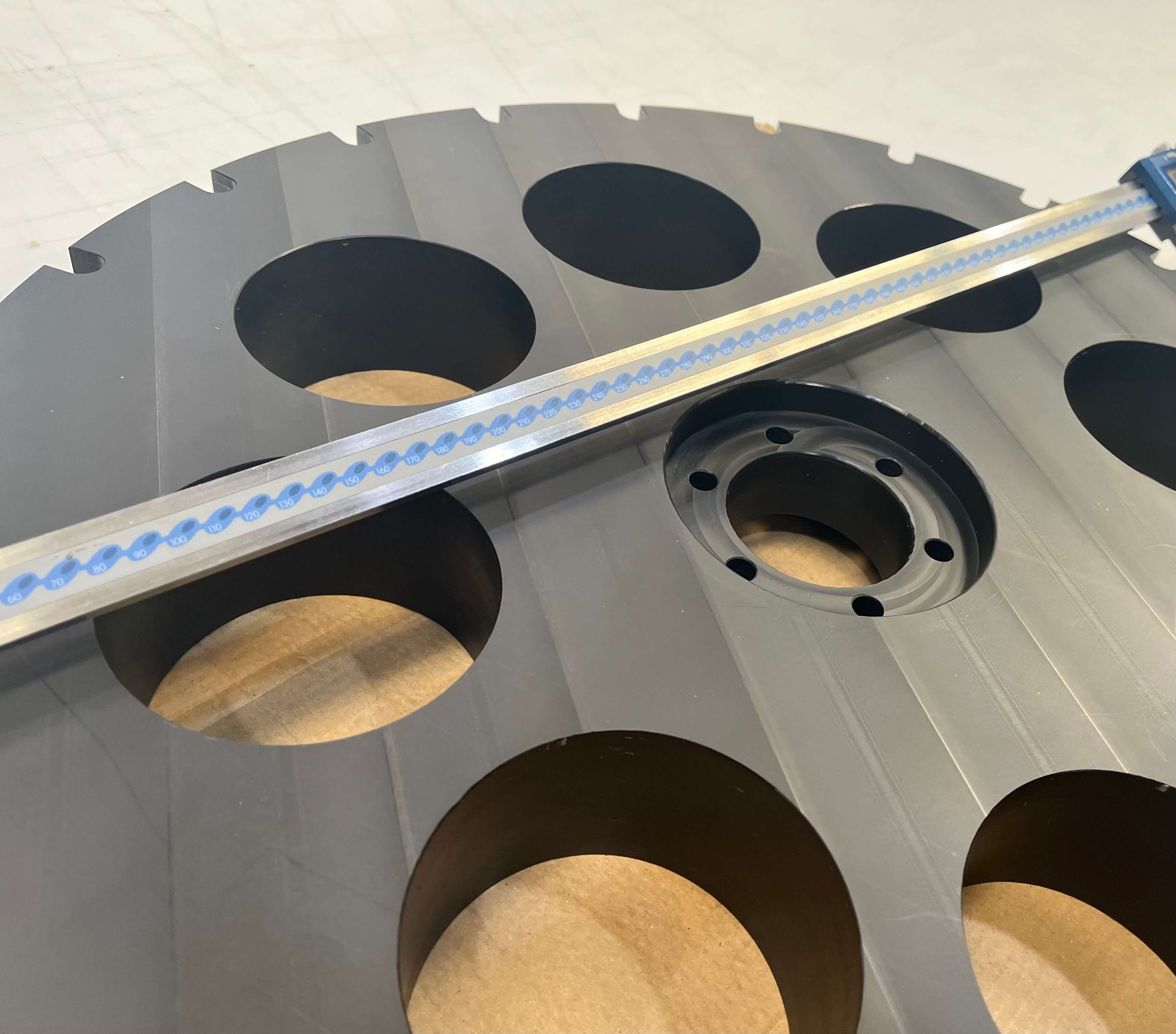

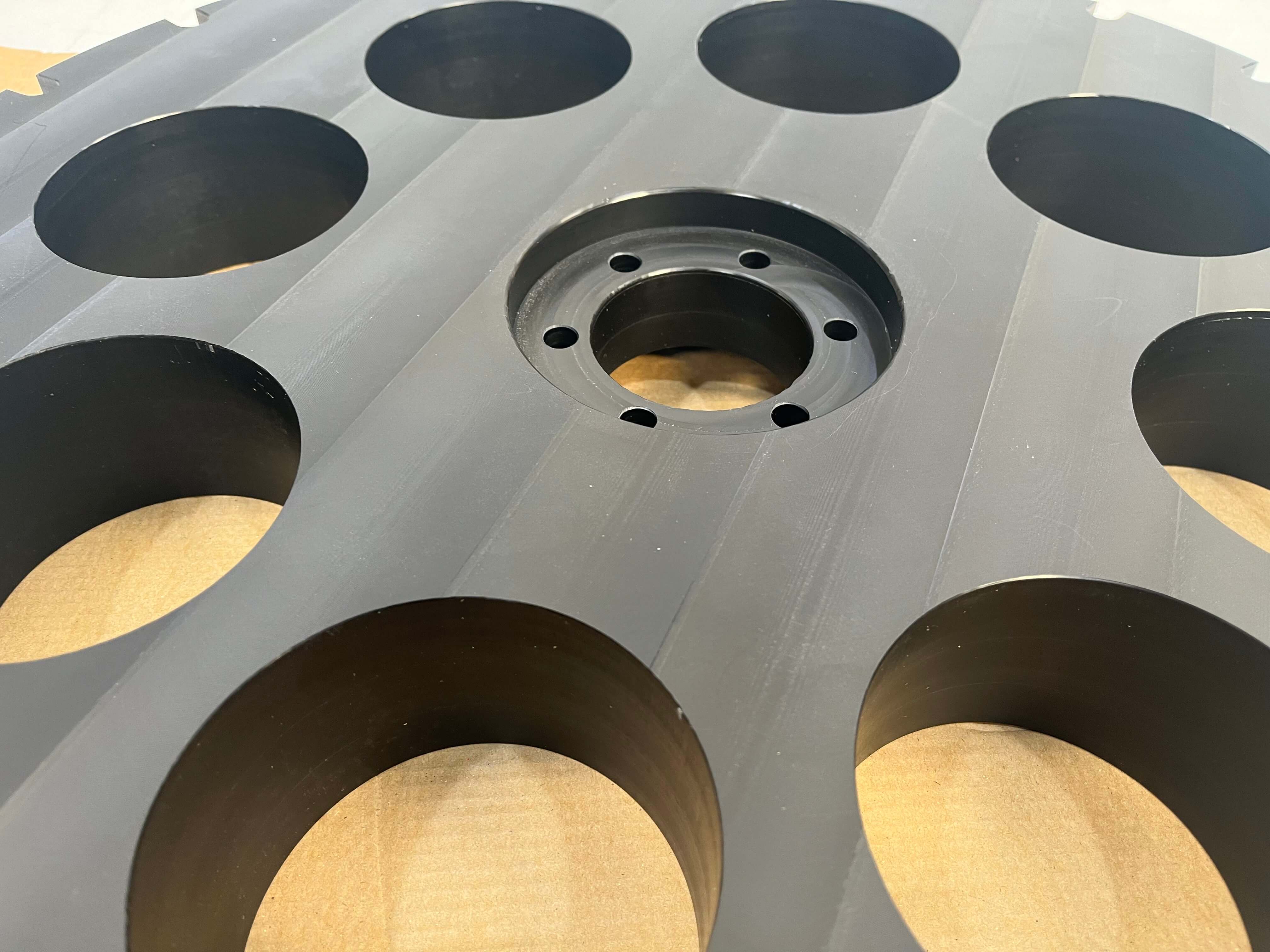

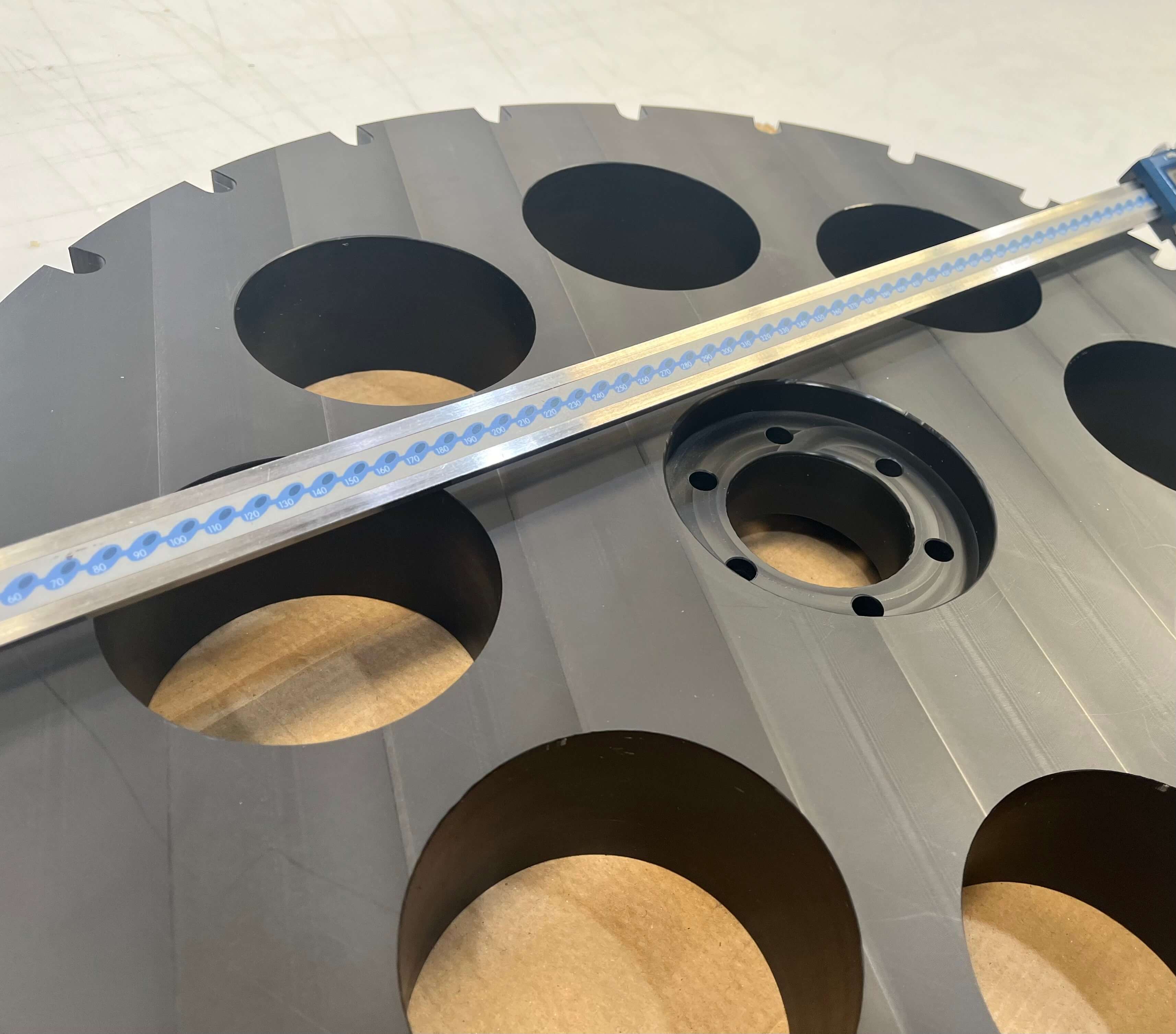

The power sheave wheel, made from black acetal using plastic engineering and machining is a vital component in various mechanical applications.

The wheel is designed to withstand the demanding environments often encountered in subsea operations.

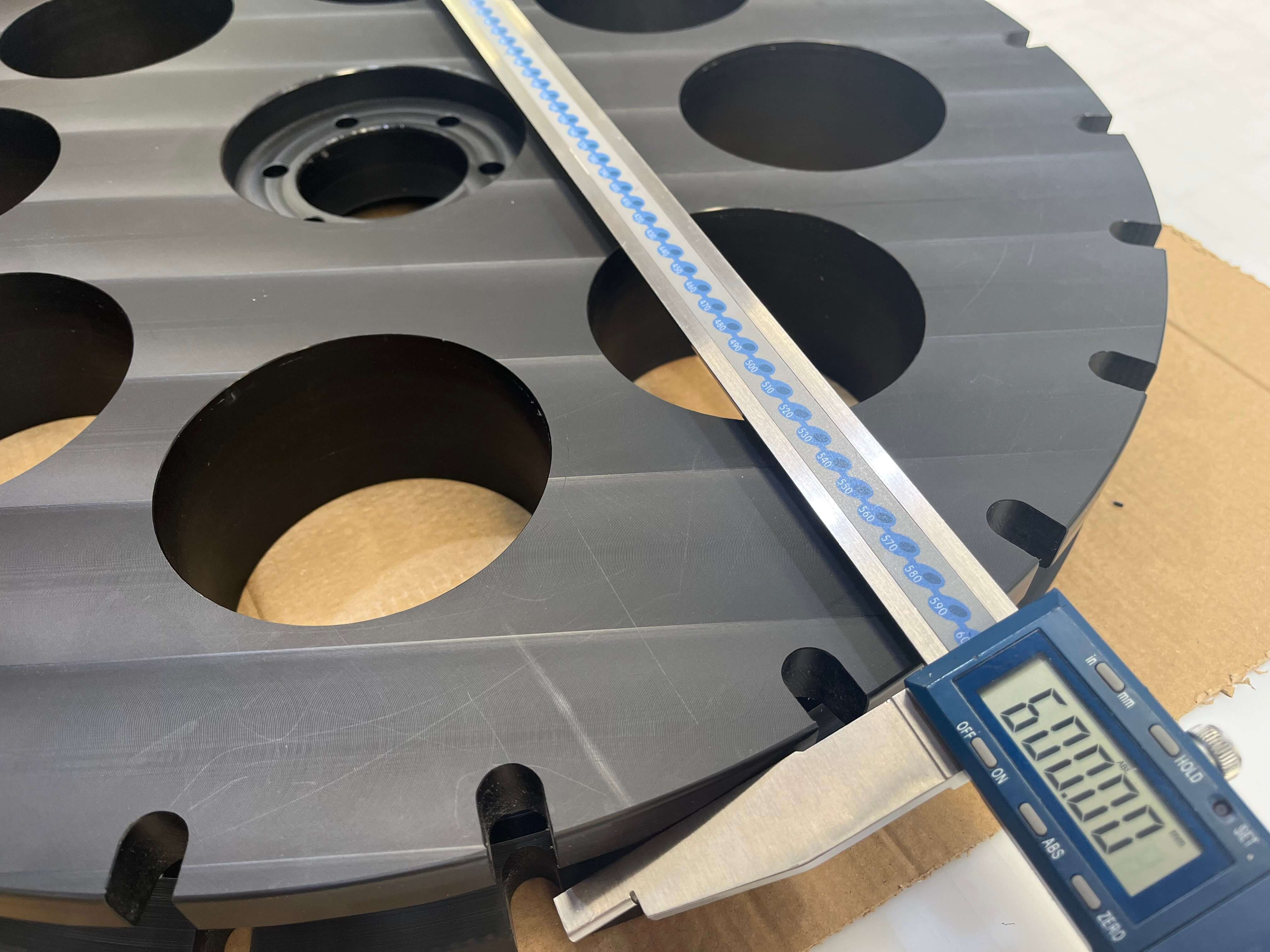

Its high tolerance manufacturing ensures that it meets the stringent specifications required for effective performance.

Material

Black acetal, a thermoplastic polymer, is chosen for the power sheave wheel due to its excellent mechanical properties, including high stiffness, low friction, and exceptional dimensional stability.

These attributes make it an ideal material for high-tolerance components used in subsea applications. The manufacturing process involves precision machining to achieve the exact dimensions required, ensuring optimal performance and longevity of the wheel under extreme conditions.

What its used for

The power sheave wheel is engineered to handle the heavy loads and extreme pressures encountered in subsea environments.

The grooves along the edges provide additional grip and stability, essential for the wheel's functionality in guiding and supporting cables or ropes in subsea operations.

Summary

The power sheave wheel's primary application lies in subsea operations, where it plays a crucial role in the deployment and management of underwater cables and ropes.

Its high tolerance and durable construction ensure reliable performance, reducing the risk of mechanical failure in critical operations.

The use of black acetal enhances its resistance to wear and corrosion, offering significant advantages in terms of maintenance and operational efficiency. Overall, the power sheave wheel is a vital component that contributes to the success and safety of subsea projects.

Book your next project

At WKH, we provide a range os specialist services customised to meet the specific needs of our customers.

At WKH no project is too big, too small or too complex, for any precision engineering needs simply call on 0113 239 1909, email us or request a quote.

Get Your QuoteBlog posts

Lexan is a brand name for a type of polycarbonate resin thermoplastic developed by General Electric Plastics (now owned by SABIC). Known for its strength, durability, and optical clarity, Lexa...

Teflon, a brand name commonly associated with the chemical compound polytetrafluoroethylene (PTFE), is a synthetic fluoropolymer of tetrafluoroethylene. First developed in the 1930s by Roy Plunket...

What is the density of High Density Polyethylene?

High-Density Polyethylene (HDPE) has a density range of 0.94 to 0.97 grams per cubic centimetre (g/cm³), which sets it apart from other types of polyethylene, such as Low-Density Polyethylene (LDP...