Precision machining is a critical manufacturing process where highly detailed machined parts are produced with exceptional accuracy. These components are essential in fields like aerospace, automotive, medicine, electronics, and more. This discussion delves into what precision machining entails, its importance, the processes it involves, and the technologies driving this vital manufacturing sector.

What is Precision Machining?

Precision machining involves cutting materials from a workpiece to the lowest tolerances and finest finishes. The process requires extreme accuracy, often measured in thousandths of inches or micrometers, to create high-tolerance and precise geometries.

Importance of Precision Machining

Quality and Performance

High-precision parts ensure that machines and devices function optimally. In critical applications like aerospace and medical devices, failure is not an option.

Consistency

Precision machining allows for the production of identical parts in large quantities, ensuring consistency and reliability in mass production.

Innovation

The capability to create extremely complex high-precision parts drives innovation in technology and new product development.

Key Processes in Precision Machining

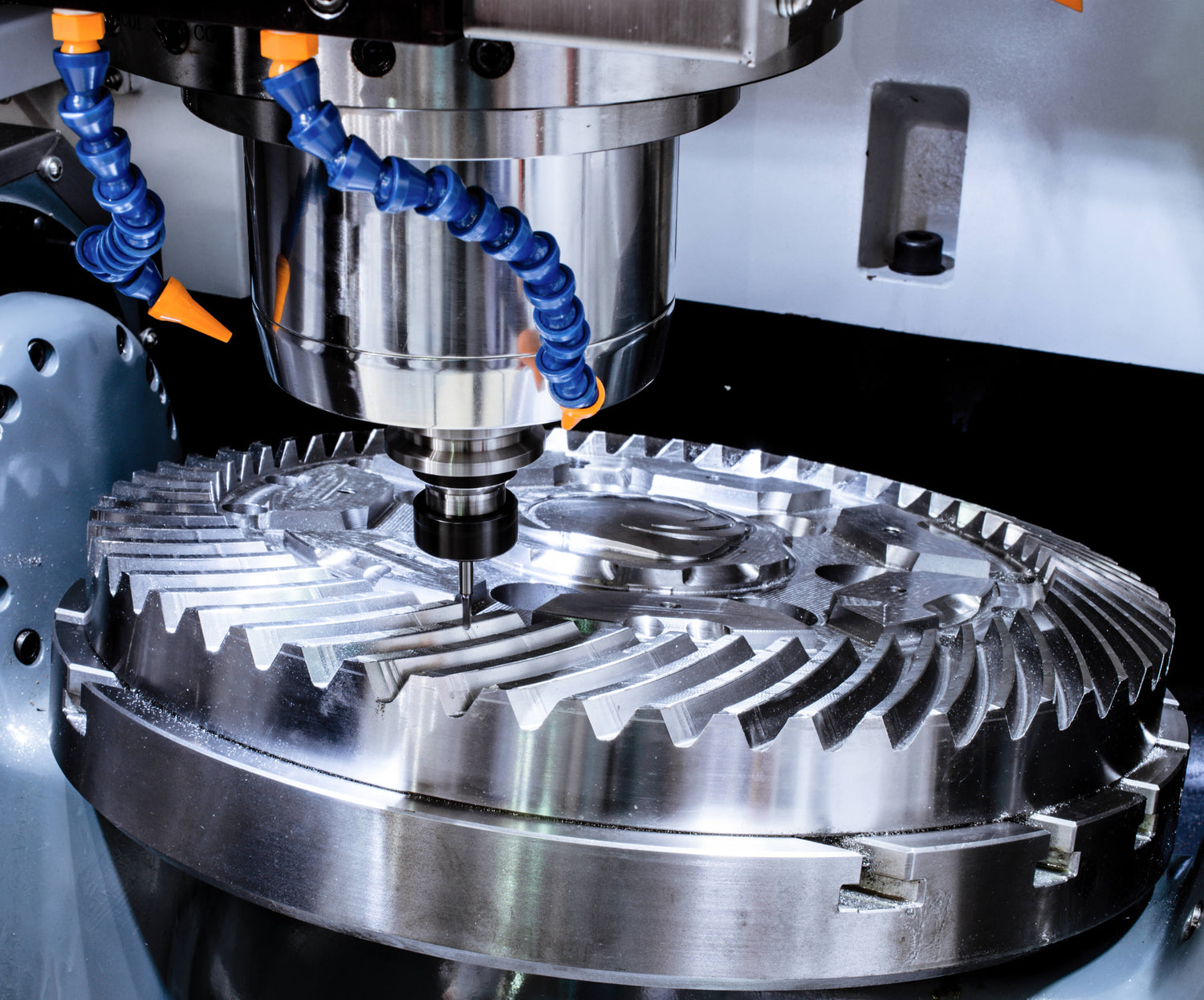

CNC Machining

Computer Numerical Controlled (CNC) machining involves highly accurate and automated machines. They operate based on programmed instructions to produce parts with exact specifications.

Milling

Milling removes material using rotary cutters. CNC milling machines can perform various point shaping operations to create intricate parts.

Turning

Turning involves rotating the workpiece in a lathe to machine it to the final size and shape. It is commonly used to produce cylindrical parts.

Grinding

A finishing operation that achieves very accurate tolerances and smooth finishes. Abrasive grains grind the surface of a workpiece, dislodging small chips.

Electrical Discharge Machining (EDM)

EDM removes material using tiny, controlled electrical sparks. It is effective for creating detailed shapes and intricate designs.

Key Ingredients of Precision Machining

CAD/CAM Software

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software help manufacturers design and produce complex and intricate parts.

Advanced Materials

The development of new materials like composites and superalloys allows for the creation of parts that perform better in severe conditions.

Metrology

Measurement tools with high accuracy, such as Coordinate Measuring Machines (CMMs) and laser scanners, ensure the integrity of parts created with close tolerances.

Industries Using Precision Machining

Aerospace

Precision machining is essential for parts like turbine blades, engine components, and landing gear, where tight tolerances are critical for safety and performance.

Automotive

Precision-machined parts in engines and transmissions enhance vehicle efficiency and longevity.

Medical Devices

High-precision components are crucial for surgical instruments, implants, and diagnostic equipment.

Electronics

The electronics industry relies on precision machining to produce small, intricate components for microchips, connectors, and other applications.

Conclusion

Precision machining is a fundamental aspect of modern manufacturing, enabling the production of high-quality, complex parts used in various industries. Advanced technology and processes in precision machining ensure high levels of accuracy and consistency, leading to improved product performance and supporting innovation and growth across major sectors.

Understanding the intricacies of precision machining highlights its vital role in advancing technology and industry, making it an indispensable field in modern manufacturing.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.