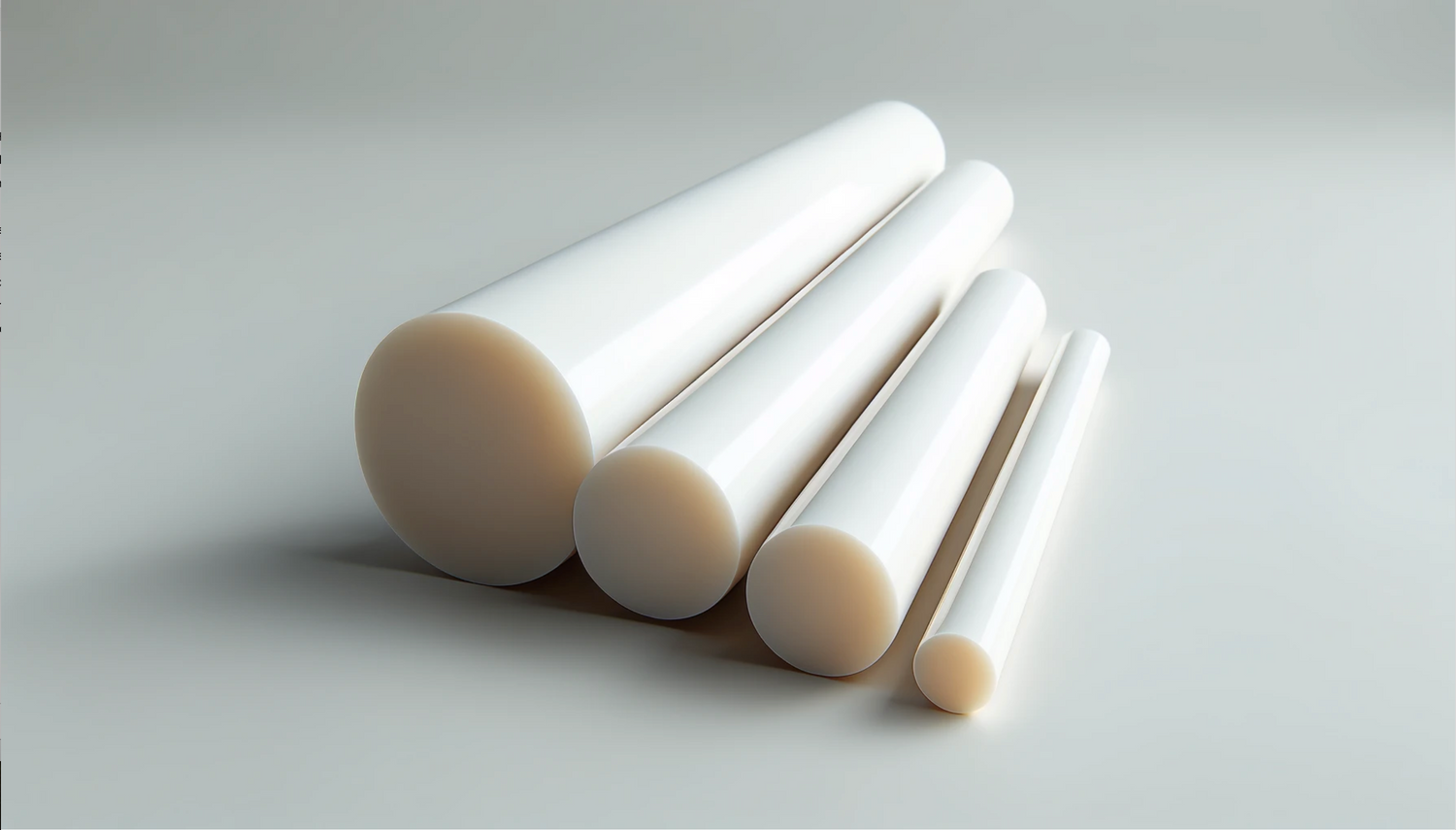

Polyoxymethylene Copolymer (POM-C) is a high-performance engineering plastic known for its excellent mechanical properties, low friction, and high dimensional stability. This article aims to provide a detailed overview of POM-C, exploring its properties, applications, advantages, and processing methods.

Properties of POM-C

POM-C, or Polyoxymethylene Copolymer, is known for its exceptional mechanical, thermal, chemical, and electrical properties, making it a highly versatile material.

- Mechanical Strength: POM-C has high strength and stiffness, which ensures reliable performance in demanding applications.

- Low Friction & Wear Resistance: It features a low coefficient of friction, making it ideal for moving parts where durability is crucial.

- Thermal Stability: POM-C maintains stability across a wide temperature range, from -40°C to 120°C, and exhibits low water absorption. This contributes to its dimensional stability, even in humid conditions.

- Chemical Resistance: It resists solvents, fuels, and oils, although it is not suitable for strong acids and bases.

- Electrical Insulation: POM-C is an excellent electrical insulator, suitable for various electronic components.

Applications of POM-C

POM-C's versatility allows it to be used in multiple industries:

- Automotive: Commonly used for gears, bearings, and fuel system components due to its wear resistance and chemical durability.

- Consumer Goods: Found in fasteners and household appliances, such as coffee machines and dishwashers.

- Industrial Applications: Utilised in machine parts and conveyor belt components, where its strength and low friction are beneficial.

- Electrical and Electronics: Ideal for insulating components thanks to its excellent electrical properties.

Advantages of POM-C

POM-C offers several advantages, including:

- Machinability: It is easy to fabricate into complex and precise parts.

- Dimensional Stability: Its low water absorption and thermal stability ensure components maintain their shape over time.

- Surface Finish: POM-C delivers a high-quality finish, making it suitable for both functional and aesthetic applications.

- Fatigue Resistance: It performs well under repeated stress, making it suitable for dynamic applications.

Processing and Machining of POM-C

POM-C can be processed through various methods, including:

- Injection Moulding: Requires careful temperature control and tool design to prevent material degradation.

- CNC Machining: Needs sharp tools and effective cooling to avoid overheating and deformation.

- Extrusion: Must be closely monitored to ensure consistent dimensions and properties.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.