Reduce ESD: Enhance Safety & Productivity

ATEX - Generally refers to the hazard of explosive atmospheres occurring in the workplace due to the presence of flammable gasses or combustible dust mixed in the air, which can give rise to the risk of explosion.

Antistatic & or Static Dissipative materials can help reduce risk of explosion.

A dissipative material has medium surface resistivity, meaning electricity flow through slow & with greater control than conductive material. Also known as Static-Dissipative or Electro-Dissipative material.

Dissipative material is best for ESD Environments since it allows charges to flow slowly & in a controlled manner.

HELP TO PREVENT ESD EVENTS

Even though it is impossible to eliminate ESD from your operation completely, there are ways to prevent electrostatic discharge.

Materials - Such as Clear Polycarbonate PC350 Static Dissipative Sheet. Used for Guarding/Screens/Doors will control particulate attraction & prevent discharge (ESD) events independent of humidity.

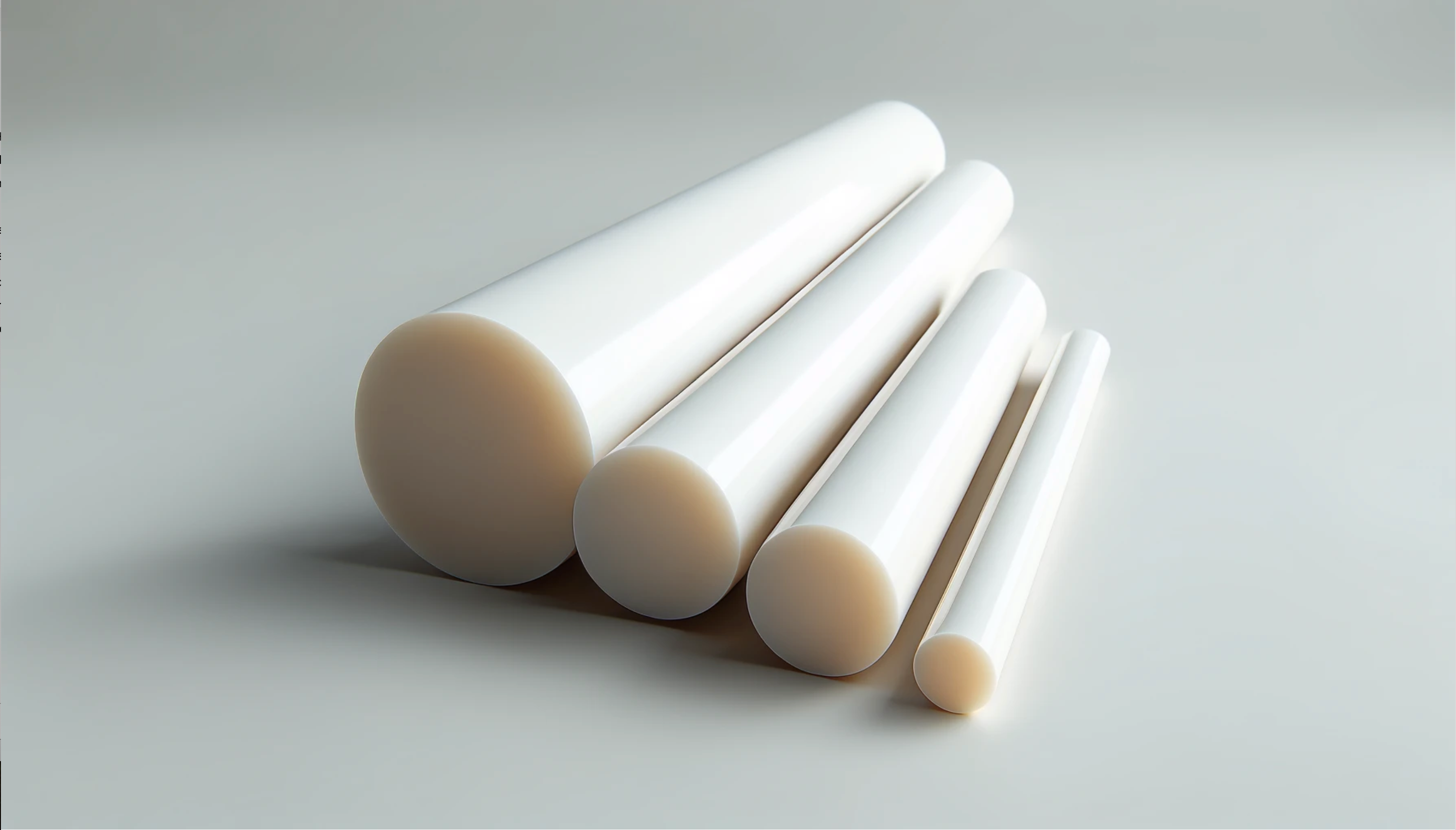

Static Dissipative Acetal, Conductive PTFE and Antistatic Polyethylene are also available for components that require static dissipative properties.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.