The Evolution of Metal Fabrication

Before CNC Metal Machining: The History of Metal Fabrication Before the advent of CNC machining, metal fabrication relied heavily on manual labor and conventional machining techniques. While effective to some extent, these methods often lacked precision and repeatability, resulting in products with inconsistencies. The introduction of CNC technology revolutionised manufacturing by enhancing accuracy and consistency.

The CNC Metal Machining Process

How CNC Metal Machining Works At the heart of CNC metal machining is the sophisticated interplay of hardware and software. The process begins with a digital design created on a Computer-Aided Design (CAD) platform, serving as a blueprint for the final product. This design details each dimension and contour with meticulous precision.

Once finalised, the design is translated into machine-readable instructions called G-code, which guides the movements of the cutting tools. These instructions are fed into the CNC controller, which orchestrates the entire machining operation with precision timing and coordination.

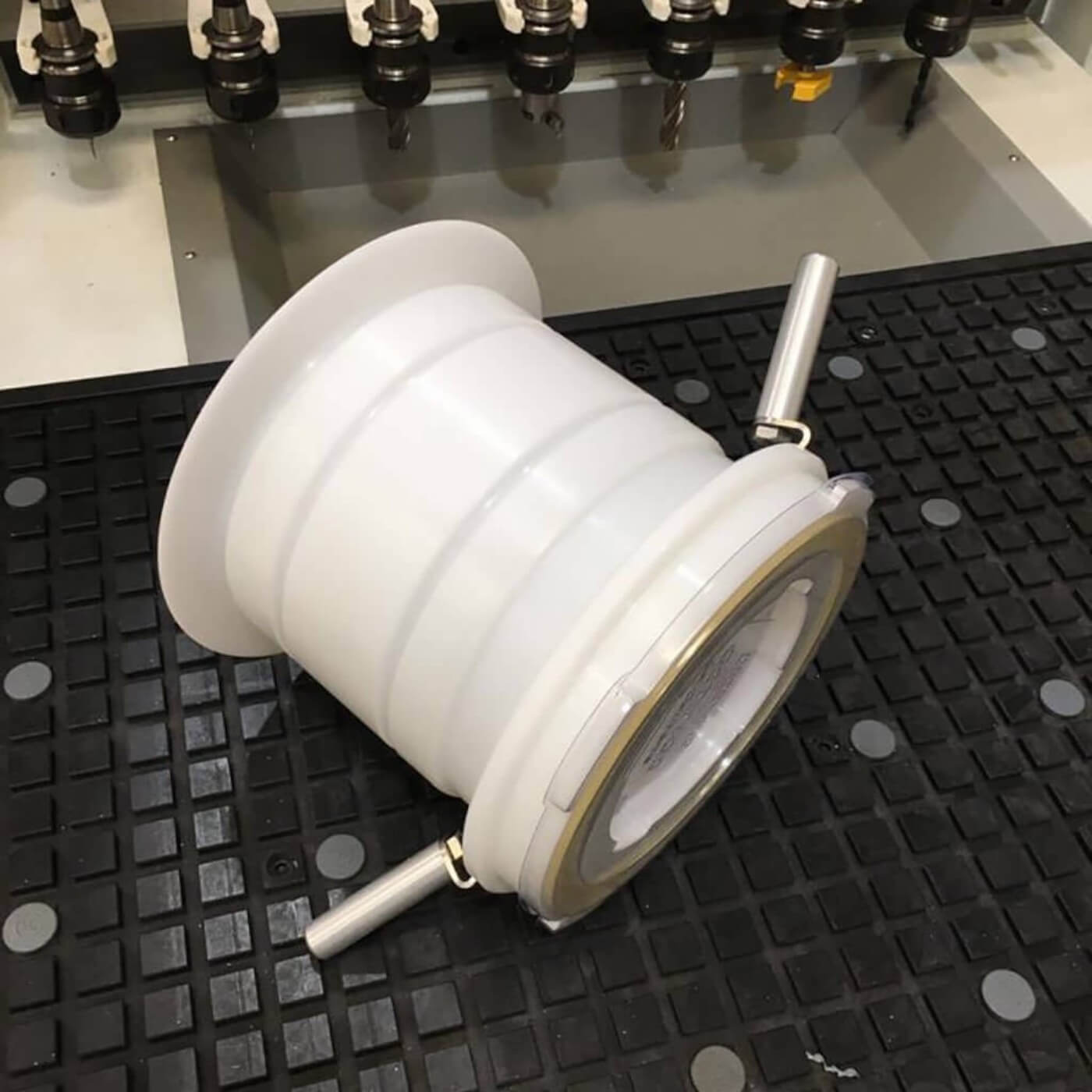

The CNC machine comprises various critical components: the workpiece, cutting tools like drills, mills, lathes, the spindle, and an axis system. As the machine executes the program instructions, the cutting tools engage with the workpiece, gradually removing material to achieve the final shape and dimensions.

Advantages of CNC Metal Machining

CNC metal machining is widely practiced for several compelling reasons:

-

Accuracy: The precision of CNC machines allows for the creation of intricate geometries and tight tolerances unattainable by manual methods.

-

Efficiency: Automation reduces lead times and increases productivity. Complex parts can be made rapidly and consistently, optimising production output.

-

Flexibility: CNC machines can handle a wide range of materials, including aluminium, steel, titanium, and alloys, making them valuable across industries such as aerospace, automotive, medical, and electronics.

-

Cost-Effectiveness: Despite the substantial initial investment in CNC equipment, long-term cost savings are significant due to lower labor costs, reduced material waste, and increased efficiency, offering a strong return on investment.

-

Quality Control: CNC machining ensures consistent quality by producing components to exact specifications, reducing defects and ensuring uniformity from batch to batch.

Innovations in CNC Metal Machining

Continuous advancements in technology are reshaping CNC metal machining, pushing the boundaries of what is possible.

Multi-Axis Machining By adding more axes of motion, such as simultaneous rotation and tilting, multi-axis CNC machines can approach complex geometries from multiple angles, allowing the production of highly intricate parts with fewer setups.

High-Speed Machining Advances in spindle technologies, tooling, and control systems have led to high-speed machining techniques. These enable faster material removal rates and reduced cycle times without sacrificing precision.

Additive Manufacturing While subtractive machining remains the predominant technique for metal fabrication, additive manufacturing, or 3D printing, is gaining traction as a complementary method. Additive manufacturing builds part geometry layer by layer, offering unprecedented design freedoms and the capability to produce complex geometries with minimal waste.

In summary, CNC metal machining stands at the forefront of precision engineering, continually evolving to meet the demands of modern manufacturing with unparalleled accuracy, efficiency, and innovation.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.