This component is a custom-machined aluminium part, engineered to integrate into a more extensive mechanical assembly. Its primary use is for organisations specialising in the development of advanced prosthetic devices, rehabilitation equipment, and mobility solutions. These companies require robust, lightweight materials to ensure durability while maintaining user comfort in their final products.

Materials and Construction:

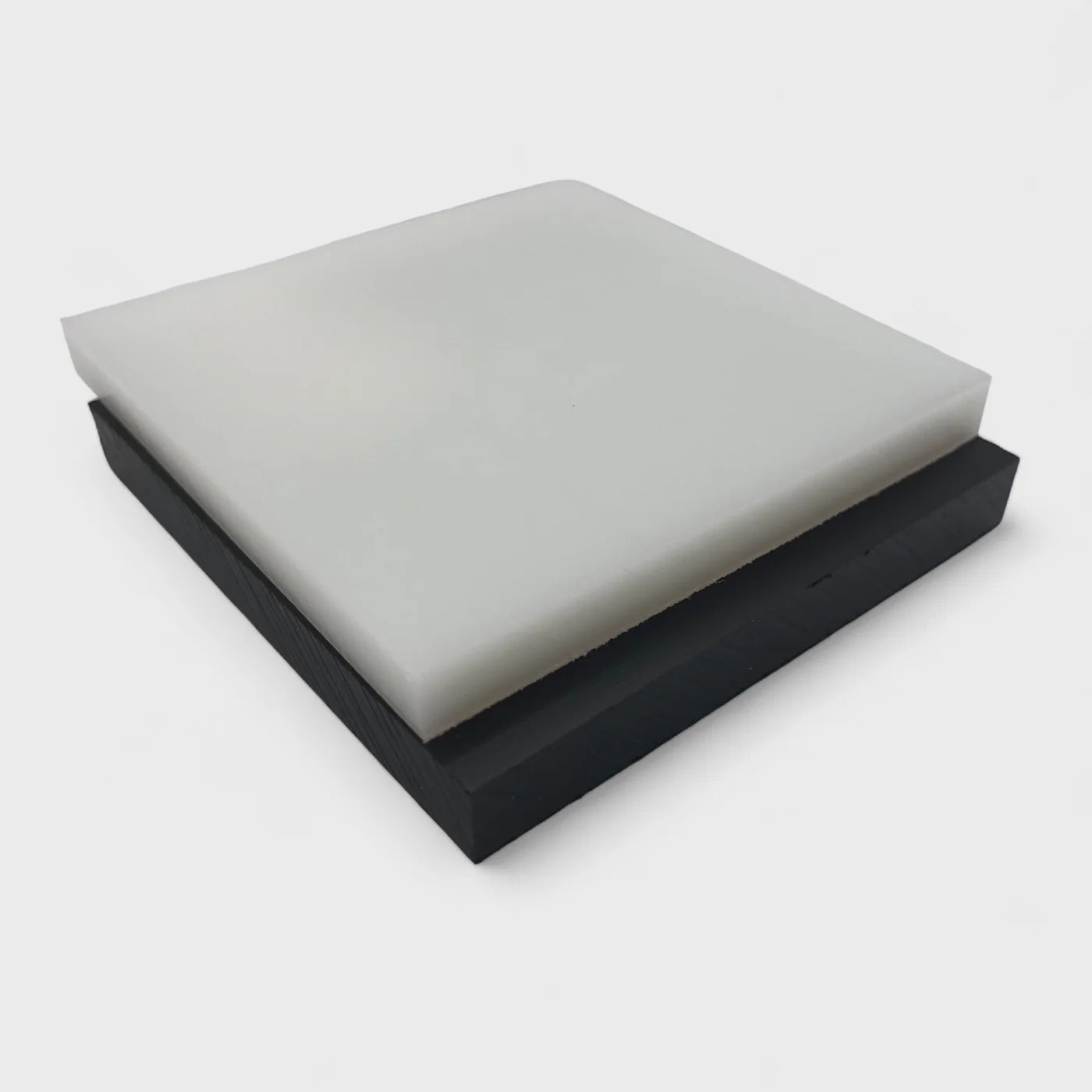

The component is made from high-grade aluminium, chosen for its balance of strength and lightweight properties. Aluminium's corrosion resistance ensures longevity and reliability in varied environments, making it an ideal choice for applications where consistent performance is crucial.

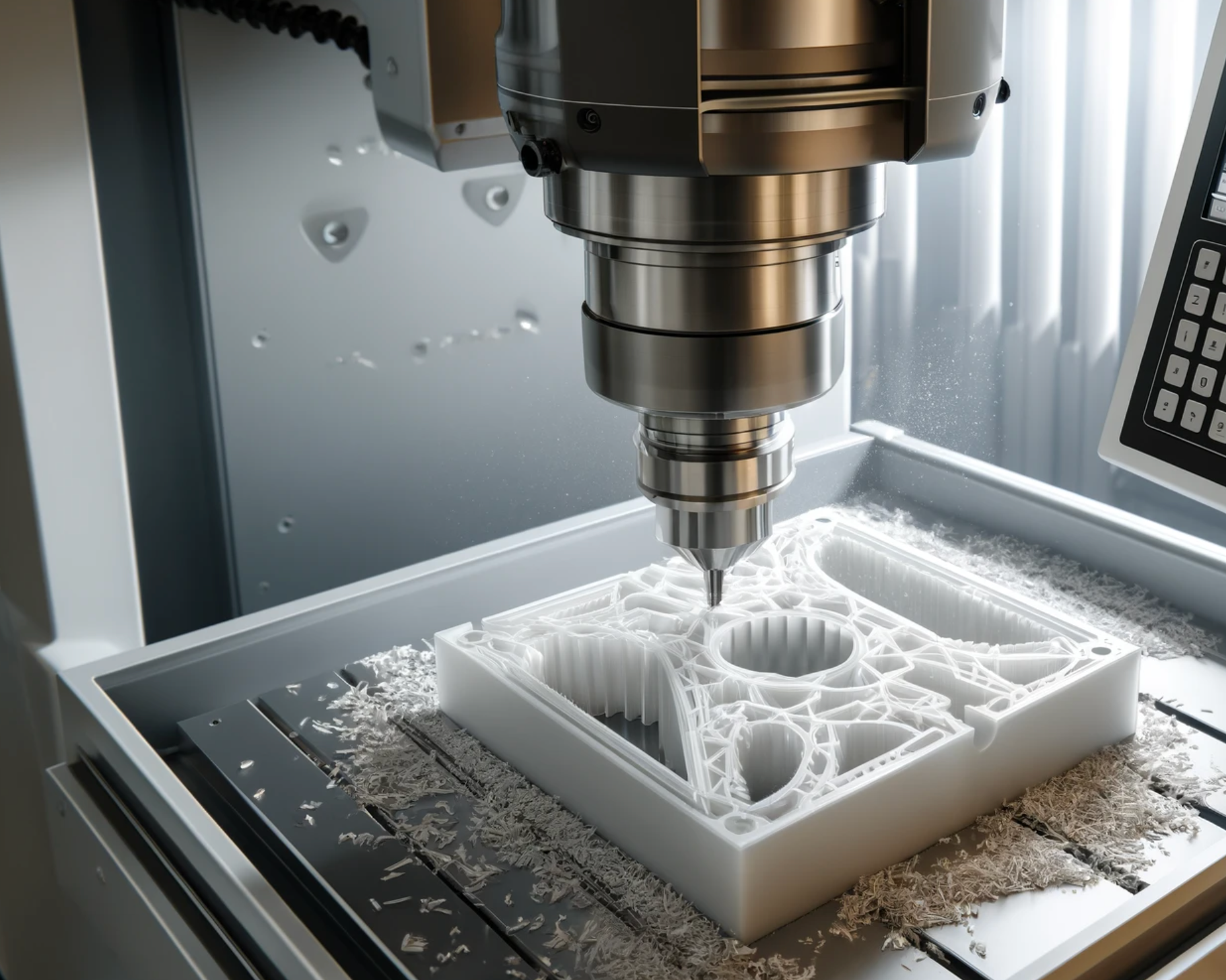

The part is CNC metal machined, providing tight tolerances and a smooth finish, essential for ensuring a precise fit within the larger mechanical system. This machining process guarantees uniformity across each unit produced, ensuring reliability and reducing assembly complications.

Features and Specifications:

- Lightweight Construction: The aluminium body reduces overall weight, vital in mobility applications where reducing the load is essential for user comfort and energy efficiency.

- Threaded and Non-Threaded Openings: The component features both threaded and non-threaded sections, indicating its role in connecting and securing other parts within the assembly. These threads allow for secure attachments while maintaining ease of disassembly for maintenance or replacement.

- Durable Finish: A black anodised coating protects the component from environmental wear and tear, adding a layer of oxidation resistance while contributing to the sleek aesthetic of the device.

- Modular Design: The part's design includes circular openings and prongs, suggesting modularity and versatility in its integration into various prosthetic or mechanical systems. This adaptability is critical in creating customisable solutions for different users' needs.

Functionality:

This component is likely designed to act as a connector or joint in a larger mechanical framework. It may serve as part of a pivotal or rotational mechanism, common in prosthetic devices, where secure and smooth movement is essential for mimicking natural limb function. The precision of the machining ensures that movements are controlled and smooth, reducing wear on the prosthetic device over time.

Applications:

- Prosthetics and Orthotics: As part of a prosthetic system, this aluminium component would play a crucial role in joints or connecting limbs. Its lightweight yet strong properties contribute to the overall functionality and user comfort.

- Rehabilitation Devices: In advanced rehabilitation systems, this part could serve as a connector in complex assemblies that require repeated, precise movements, contributing to long-term durability and performance.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.