Computer-Aided Design (CAD) software is a powerful tool used across industries to create detailed digital models and technical drawings. It enables engineers, architects, product designers, and other professionals to design and modify 2D and 3D objects with precision. The key advantage of CAD software is its ability to visualise, simulate, and analyse designs, reducing errors and enhancing efficiency during manufacturing or construction processes. CAD has revolutionised traditional drafting by enabling complex geometries and intricate details that are difficult or impossible to achieve manually.

| Industries Using CAD | Examples of Applications |

|---|---|

| Aerospace and Automotive | Complex geometries, engine components, turbine blades |

| Architecture | Building designs, structural analysis |

| Consumer Products | Plastic moulds, custom parts, product prototypes |

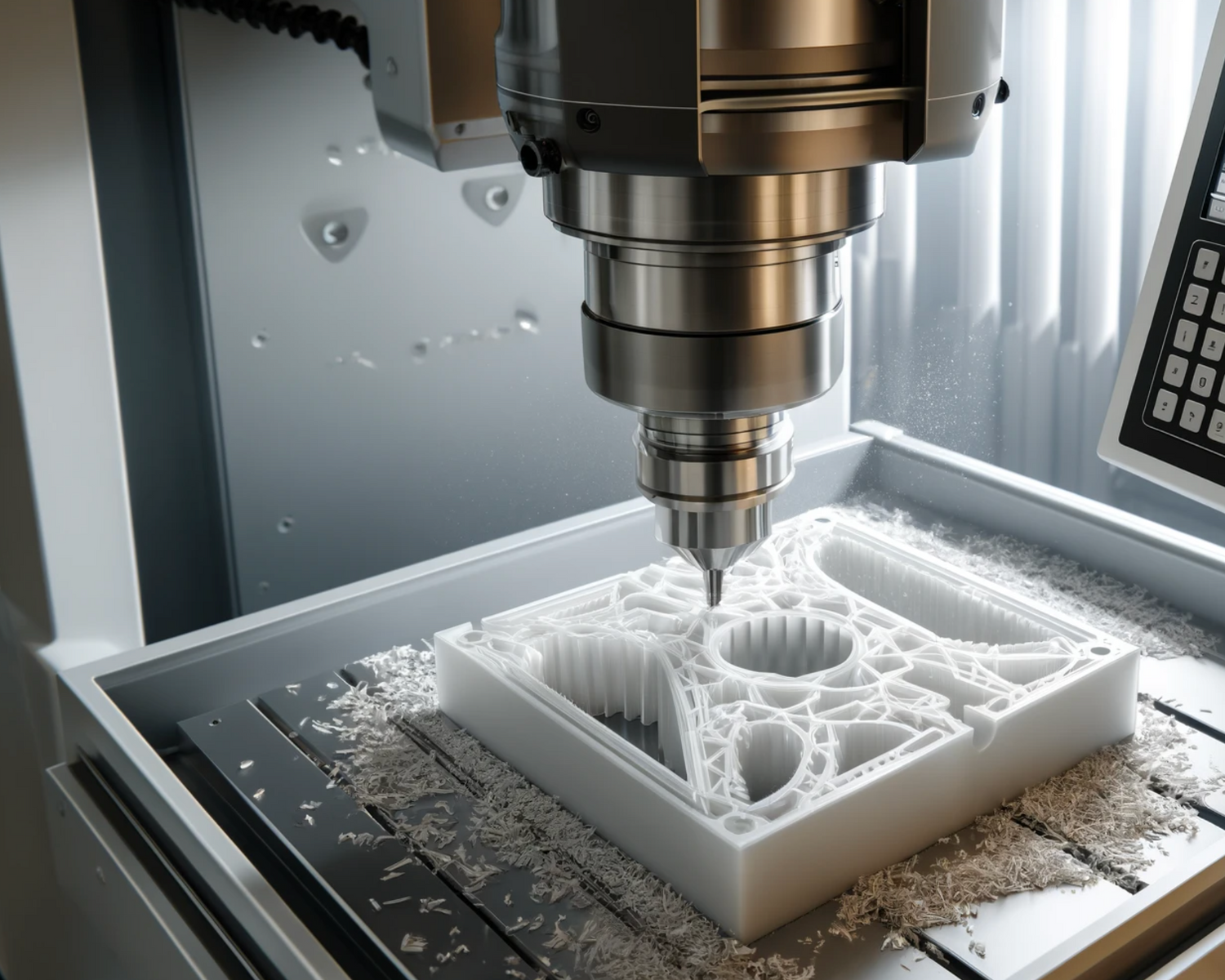

| Manufacturing | Sheet metal fabrication, tooling design, CNC machining |

CAD and CNC Machining

CNC (Computer Numerical Control) machining uses pre-programmed computer software to control machinery for cutting, drilling, or shaping materials like metal, plastic, wood, or composites. CAD plays a crucial role in this process by serving as the foundation for creating the digital designs used by CNC machines.

| Role of CAD in CNC Machining | Description |

|---|---|

| Design Creation | Detailed models or drawings are created using CAD software, including all necessary features. |

| Conversion to CNC Code | CAD files are converted into formats like G-code for machine interpretation. |

| Simulation and Testing | CAD software simulates the machining process to identify errors or collisions. |

| Precision and Accuracy | CAD ensures design accuracy for parts that fit together and meet exact specifications. |

CAD in Plastic and Metal Engineering

CAD is essential in both plastic and metal engineering, supporting the creation of products with high levels of precision and optimised designs.

Plastic Engineering

CAD software helps in optimising designs, mould creation, and product testing for plastics.

| Role of CAD in Plastic Engineering | Description |

|---|---|

| Design Optimisation | Engineers optimise designs for manufacturability, durability, and material usage. |

| Mould Design | CAD helps design precise mould geometries for injection moulding and extrusion. |

| Prototyping and Testing | Virtual testing of plastic components helps identify weaknesses before production. |

| Customisation | Custom plastic parts can be quickly and cost-effectively designed using CAD. |

Metal Engineering

In metal engineering, CAD supports complex part design, sheet metal fabrication, and structural analysis.

| Role of CAD in Metal Engineering | Description |

|---|---|

| Design of Complex Parts | Engineers create parts with complex geometries, such as turbine blades and engine components. |

| Sheet Metal Fabrication | CAD helps design parts that will be cut, bent, or shaped from sheet metal. |

| Structural Analysis | CAD models undergo Finite Element Analysis (FEA) to test strength and durability. |

| Tooling and Fixture Design | CAD is used to design tools and fixtures for manufacturing metal components. |

| 3D Printing and Metal Additive Manufacturing | CAD enables the creation of intricate metal designs for 3D printing. |

Conclusion

CAD software is indispensable in modern manufacturing, particularly in CNC machining and plastic/metal engineering. By facilitating the precise creation of digital models, CAD ensures that manufacturing processes like machining or moulding are carried out accurately and efficiently. Whether designing plastic moulds for consumer products or fabricating critical metal components for aerospace applications, CAD improves workflow, accuracy, and reduces errors.

| Summary of CAD Advantages | Impact |

|---|---|

| Enhanced Design Accuracy | Reduced margin of error, higher quality products |

| Workflow Streamlining | Faster and more efficient production processes |

| Support for Innovation | Enables more innovative and complex product designs |

As technology continues to evolve, CAD will remain a key driver of innovation in engineering and manufacturing.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.