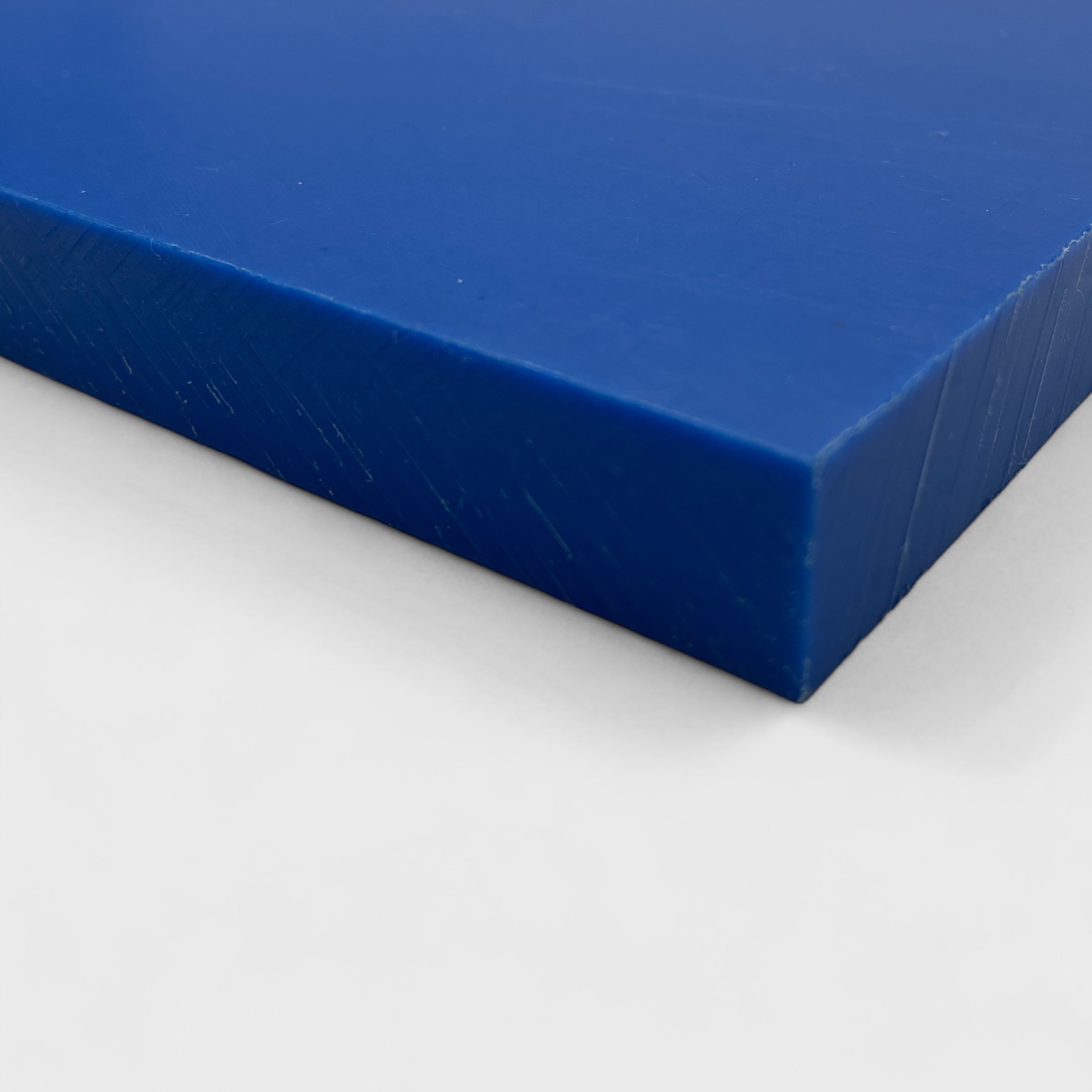

Polyethylene is a versatile polymer with numerous applications across various industries. Among its types, PE1000, also known as Ultra-High Molecular Weight Polyethylene (UHMWPE), stands out for its exceptional properties. This article explores the specifics of PE1000 Polyethylene UHMWPE, focusing on its conductive antistatic variant, and examines its properties, applications, benefits, and processing techniques.

Key Properties of UHMWPE PE1000

PE1000 UHMWPE is known for its high impact resistance, allowing it to endure significant impacts without breaking. It features a low coefficient of friction for smooth operation, which reduces wear and extends the lifespan of components while lowering maintenance costs.

The material is chemically resistant to acids, alkalis, and solvents, making it suitable for abrasive environments. Additionally, its biocompatibility ensures safety in medical and food processing applications.

Conductive Antistatic UHMWPE

The conductive antistatic variant of PE1000 UHMWPE includes conductive fillers that prevent hazardous static electricity buildup. This property is crucial for protecting sensitive electronic components from electrostatic discharge (ESD) and enhancing safety in industries dealing with flammable materials. Additionally, its antistatic features reduce cling and adhesion, facilitating smoother operations in material handling and packaging.

Applications of Conductive Antistatic UHMWPE

Conductive antistatic UHMWPE is widely used in the electronics sector for conveyor parts and workstations to reduce ESD risks. In material handling and packaging, it is ideal for storage bins and containers, helping to maintain cleanliness and protect sensitive items.

In the chemical and pharmaceutical industries, its properties ensure safe handling of volatile substances and compliance with hygiene standards during production and packaging.

Processing and Fabrication of UHMWPE

UHMWPE (PE1000) can be processed using conventional machining methods, and its machinability is minimally affected by conductive fillers. Welding techniques like hot gas and extrusion welding are suitable for creating larger components, while extrusion and injection moulding methods are effective for mass production, ensuring consistent quality in final products.

Understanding PE1000 UHMWPE's properties and applications enables industries to leverage its benefits for improved performance and safety. This material is available from WKH Group in PE1000 sheets and rods. For enquiries, call 0113 239 1909 or email enquiries@wkhgroup.co.uk.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.