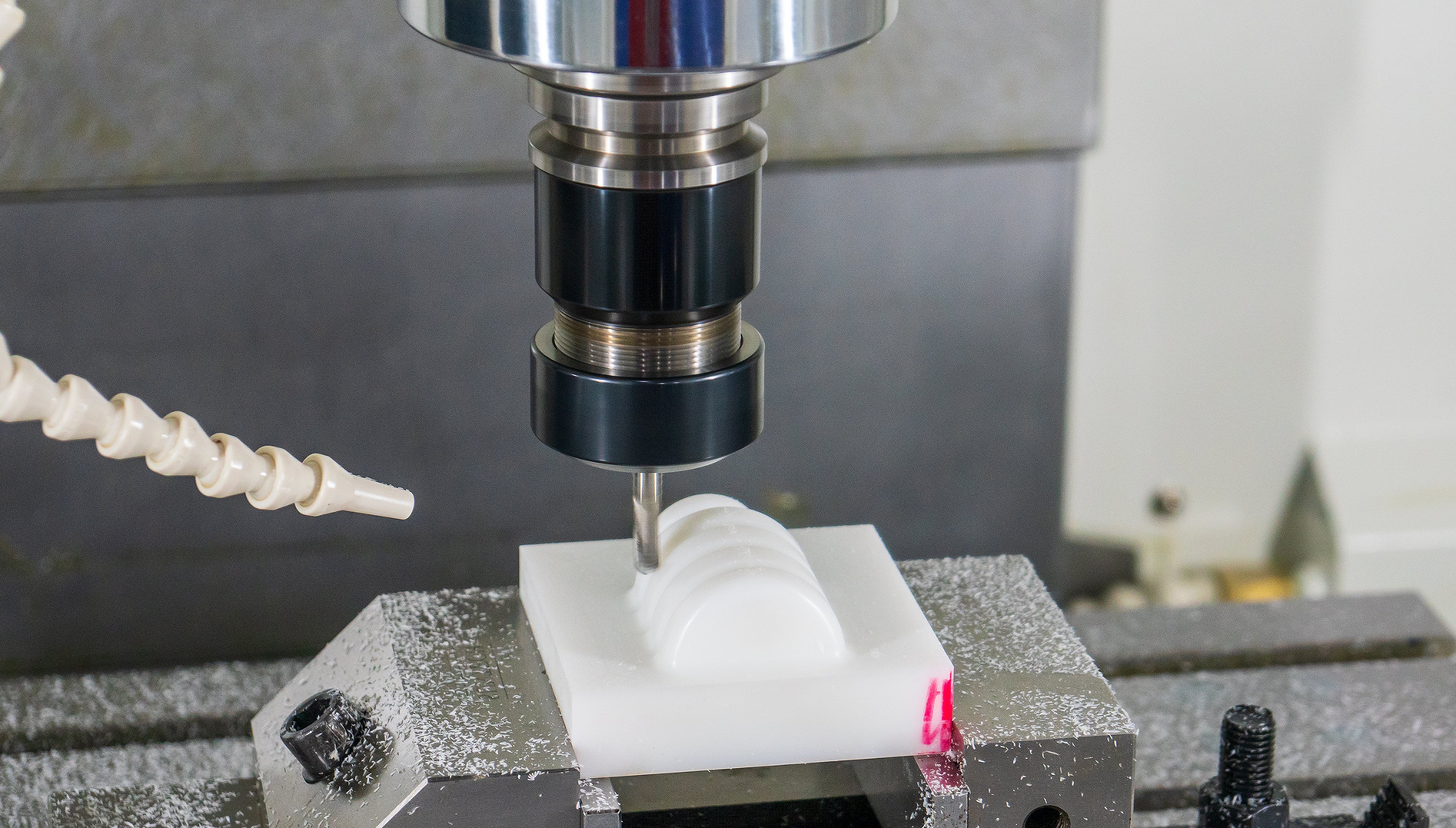

Engineering plastics are integral to many industries, offering exceptional mechanical properties and versatility. These advanced materials are utilised in automotive parts, electronic devices, medical equipment, and consumer products. This article will explore the various types of engineering plastics and their unique properties and applications.

Understanding engineering plastics, also referred to as advanced or performance plastics, are a subset of polymers known for their superior mechanical, thermal, electrical, and chemical properties compared to standard plastics. They are designed to endure demanding conditions and often serve as alternatives to metals or ceramics due to their lightweight nature and excellent performance characteristics.

Types of Engineering Plastics

Several types of engineering plastics are widely used across various industries. Here’s an overview of the most common ones:

Polyethylene is renowned for its versatility and cost-effectiveness. It exists in multiple forms, such as low-density polyethylene (LDPE) and high-density polyethylene (HDPE). LDPE is flexible and often used in packaging materials, while HDPE's rigidity makes it suitable for bottles, pipes, and containers.

Polypropylene (PP)

Polypropylene is prized for its excellent chemical resistance, making it ideal for applications involving corrosive substances or high temperatures. It is used in food containers, automotive components, medical devices, and textiles.

Polycarbonate is notable for its exceptional impact resistance and transparency. This material is used in eyewear lenses, automotive headlamps, and bulletproof glass, thanks to its energy-absorbing properties without breaking.

Acrylonitrile Butadiene Styrene (ABS)

ABS is a popular choice for its toughness, impact resistance, and ease of processing. It is frequently used in consumer goods, automotive parts, and electronics.

Commonly known as nylon, polyamides come in various formulations with differing properties. They offer high strength, excellent wear resistance, and good dimensional stability, making them suitable for mechanical components and textiles.

PEEK is a high-performance engineering plastic known for its exceptional thermal and chemical resistance. It is often selected for aerospace, medical, and electronics applications that involve extreme conditions.

Widely recognised by its brand name Teflon®, PTFE is valued for its non-stick properties and chemical resistance. It is used in cookware coatings, gaskets, and seals.

Polyethylene Terephthalate (PET)

PET is commonly used for its clarity, mechanical properties, and barrier resistance. It is found in beverage bottles, food packaging, and textiles.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.