CNC machines are a cornerstone of modern manufacturing, employing computer-controlled systems to automate the movement of tools and the execution of machining processes. These machines significantly boost productivity, precision, and uniformity, making them essential across a wide range of industries.

Types of CNC Machines

- CNC Laser Cutters: These machines use a high-powered laser to cut or engrave materials with exceptional precision. They are highly versatile, capable of working with various materials including wood, plastic, metal, glass, and ceramics.

- CNC Waterjet Cutters: Utilising a high-pressure jet of water mixed with an abrasive substance, these machines can cut through a wide range of materials. They are particularly useful for materials that are sensitive to heat or require intricate cuts.

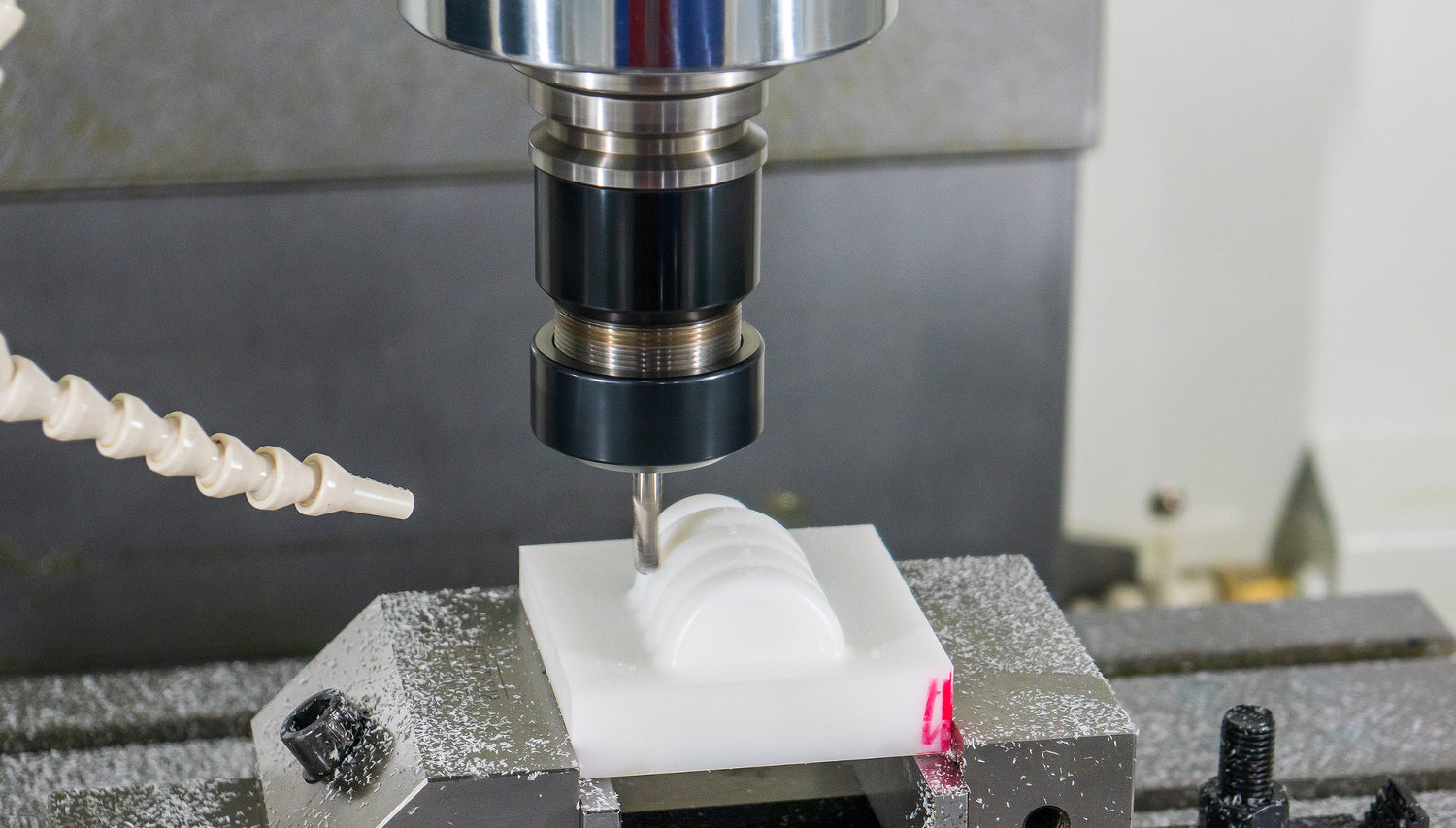

- CNC Routers: CNC routing machines use rotating cutting tools to carve out areas of a material, forming shapes or designs. They are commonly employed in woodworking, plastic fabrication, and metalworking.

- CNC Grinding Machines: These machines are designed for removing material using grinding wheels. They are often used for sanding, finishing, or polishing, particularly in industries like gear manufacturing, automotive, and aerospace.

- CNC Drilling Machines: CNC drilling machines are perfect for creating precise holes in various materials. They are widely used in industries such as automotive manufacturing, shipbuilding, and woodworking.

- CNC Plasma Cutters: These machines use a plasma torch to cut through electrically conductive materials. They are commonly applied to cut steel, stainless steel, aluminium, brass, and copper, among other metals.

- CNC Lathes: CNC lathes are primarily used for shaping cylindrical workpieces. The workpiece is rotated against a cutting tool, enabling precise operations such as cutting, drilling, facing, and turning.

CNC machines are indispensable in modern manufacturing, offering unmatched precision, efficiency, and versatility. By understanding the different types of CNC machines available, manufacturers can make informed decisions to optimise their production processes and achieve superior results.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.