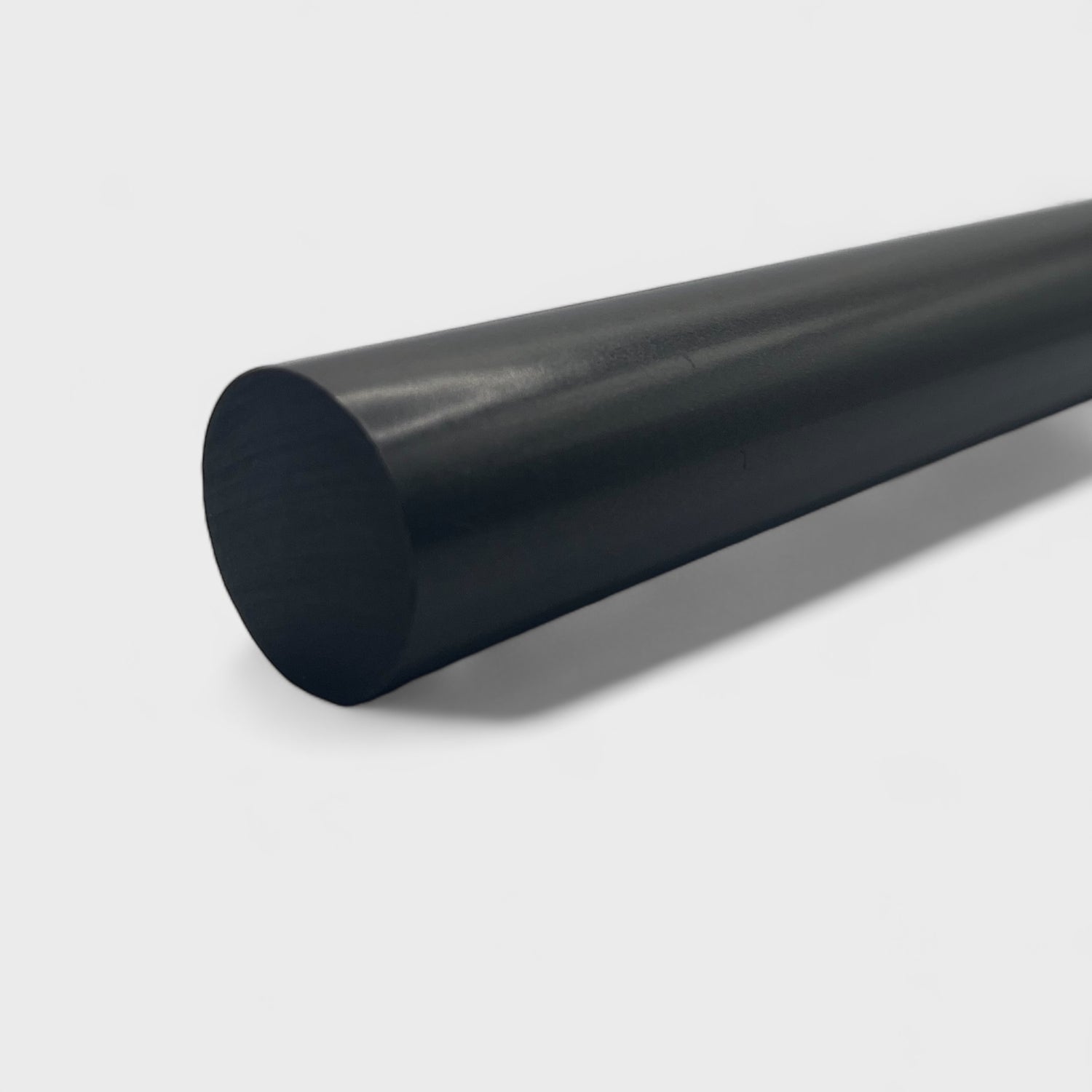

Cast Nylon 6 is a tough, wear-resistant engineering plastic used across many industries due to its versatility and durability. It can handle temperatures up to +110°C for long-term use and 170°C for short-term, making it a go-to material in demanding environments.

What are the key properties of Cast Nylon 6?

| Property | Description |

|---|---|

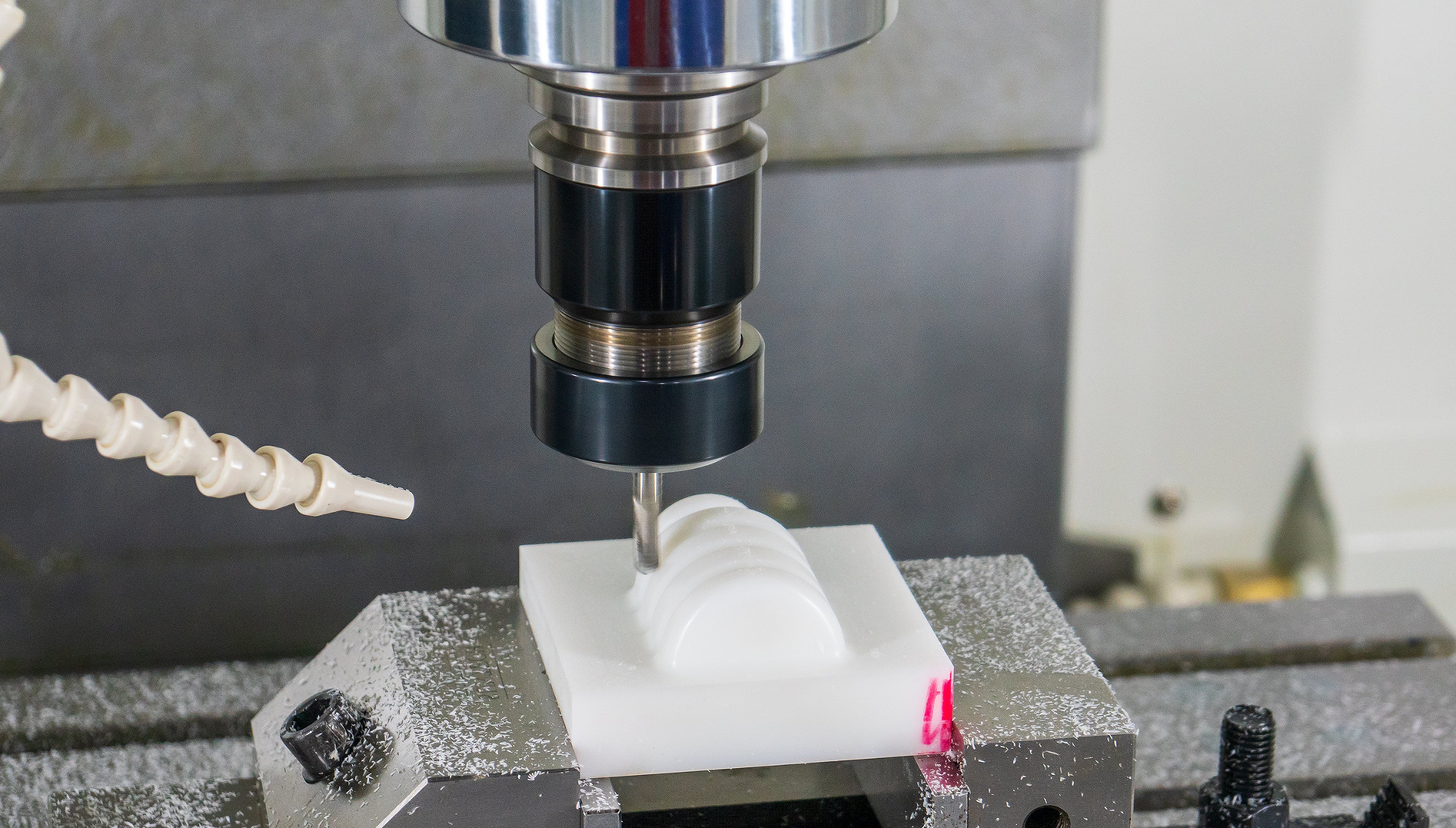

| Machinability | Easily machined using CNC for high-precision components. |

| Abrasion Resistance | Highly resistant to wear and friction, ensuring long-lasting performance. |

| Temperature Range | Functional from -40°C to +110°C, withstanding short-term peaks up to 170°C. |

| UV Resistance | Well-suited for outdoor applications, offering strong protection against UV rays. |

What are the applications of Cast Nylon 6?

| Application | Description |

|---|---|

| Mechanical Engineering | Used for durable parts in machinery. |

| Wear Parts | Ideal for bushings, bearings, and liners due to its resistance to wear. |

| Conveyor Systems | Low friction makes it perfect for sliding parts, rollers, and pulleys. |

| Gears & Cogs | Lightweight and corrosion-resistant, offering low wear compared to metal alternatives. |

| Precision Parts | Common in industries requiring close-tolerance components, like electronics and automotive. |

Cast Nylon 6 is a reliable, versatile material used in everything from mechanical engineering to conveyor systems. Its strength, machinability, and wear resistance make it a staple in many industries, and as technology evolves, its use will only continue to grow.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.