Clear cast acrylic sheets are highly valued for their transparency, strength, and adaptability, making them a go-to material for professionals in various industries. With the addition of Peerguard coating, these sheets gain extra durability and scratch resistance, extending their lifespan and offering more reliable performance. In this article, we’ll explore the features, uses, and benefits of clear cast acrylic sheets with Peerguard coating, and explain why they’re a preferred choice for many applications.

What Are Clear Cast Acrylic Sheets with Peerguard Coating?

Composition and Structure

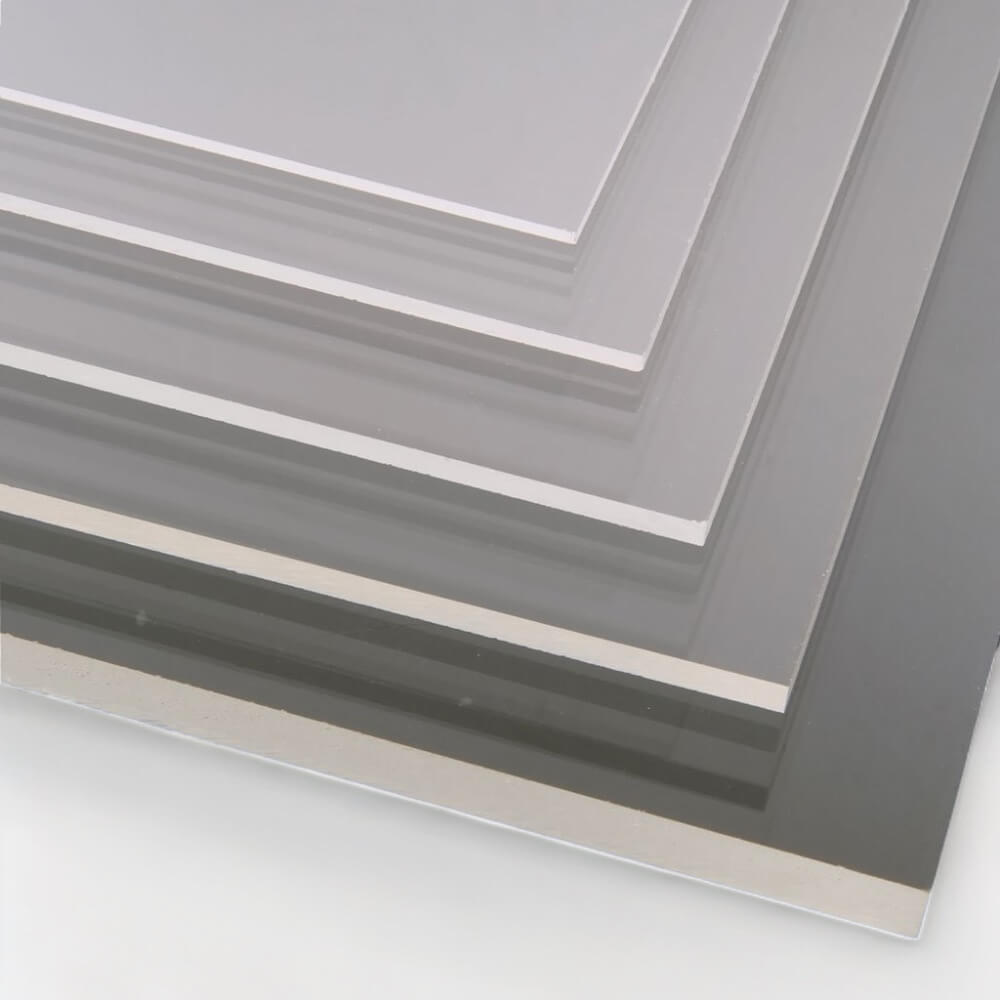

Cast acrylic sheets are made by pouring liquid acrylic between glass plates. This process ensures the material has excellent optical clarity and a consistent thickness.

- Optical Clarity: Cast acrylic allows exceptional light transmission, making it a popular alternative to glass.

- Strength and Durability: Stronger than many other plastics, cast acrylic is highly impact-resistant, ensuring long-lasting performance.

- Lightweight: Though durable, cast acrylic is much lighter than glass, making it easier to handle and install.

Peerguard Coating

The Peerguard coating adds a layer of protection, enhancing the acrylic sheet’s surface properties.

- Scratch Resistance: The coating creates a harder surface, reducing the risk of scratches and abrasions, which helps maintain the sheet’s clarity over time.

- UV Protection: Peerguard offers UV resistance, preventing the sheet from yellowing or degrading due to sunlight exposure.

- Chemical Resistance: The coating also guards against various chemicals, making these sheets suitable for harsher environments.

Applications of Peerguard-Coated Cast Acrylic Sheets

Architecture and Design

Thanks to their aesthetic qualities and practical advantages, Peerguard-coated acrylic sheets are widely used in design and architecture.

- Windows and Skylights: Their transparency and UV resistance make them ideal for windows and skylights, providing natural light while maintaining durability.

- Partitions and Dividers: Often used in modern office spaces and public areas, they offer sleek, transparent separation without compromising on strength or style.

- Signage and Displays: Perfect for both indoor and outdoor signs, retail displays, and exhibition stands, thanks to their optical clarity and scratch resistance.

Automotive and Transportation

In the automotive sector, these acrylic sheets serve numerous purposes, valued for their lightweight and impact resistance.

- Vehicle Windows: Used in cars and other vehicles as a lightweight, shatter-resistant alternative to traditional glass.

- Interior Components: Found in dashboard panels, instrument clusters, and other interior parts, combining functionality with a polished appearance.

Medical and Healthcare

Peerguard-coated acrylic sheets are widely used in healthcare settings due to their clarity, hygiene, and durability.

- Protective Barriers: Often installed in hospitals and clinics as reception barriers or between patient beds, providing clear visibility while promoting hygiene.

- Medical Equipment: Used in the manufacturing of medical devices and housings, offering both strength and ease of cleaning.

Industrial Uses

In industrial environments, Peerguard-coated acrylic sheets are valued for their resilience and clarity.

- Machine Guards: Employed as protective shields in machinery, allowing workers to observe processes while staying safe.

- Control Panels: Used for instrument covers and control panels, combining transparency with chemical and scratch resistance.

Key Benefits of Peerguard-Coated Cast Acrylic Sheets

Enhanced Durability

The Peerguard coating significantly boosts the longevity of cast acrylic sheets compared to uncoated options.

- Long-Lasting Clarity: The coating helps keep the sheets clear and scratch-free, even in high-traffic areas or demanding environments.

- Weather Resistance: These sheets are resistant to UV rays and weathering, making them suitable for both indoor and outdoor use.

Practical Advantages

Peerguard-coated acrylic sheets come with several practical benefits.

- Ease of Fabrication: They can be easily cut, drilled, and shaped, making them adaptable to various project needs.

- Low Maintenance: The scratch-resistant surface requires less cleaning and maintenance, reducing upkeep over time.

- Safety: Their shatter-resistant nature provides a safer alternative to glass, especially in areas where glass breakage could be hazardous.

Cost-Effectiveness

Although the initial cost of Peerguard-coated acrylic sheets may be higher than some alternatives, their long-term advantages make them a worthwhile investment.

- Longevity: The combination of durability, UV protection, and scratch resistance ensures a longer lifespan, reducing the need for frequent replacements.

- Versatility: With a wide range of applications across multiple industries, these sheets offer a cost-effective solution for various needs.

Peerguard-coated cast acrylic sheets offer an ideal blend of durability, clarity, and resistance to environmental factors, making them a versatile choice across industries. Whether for architectural projects, automotive components, medical equipment, or industrial settings, these sheets provide long-lasting performance with minimal maintenance.

For professionals looking for a reliable, high-quality material that balances aesthetics with functionality, Peerguard-coated cast acrylic sheets are an excellent option.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.