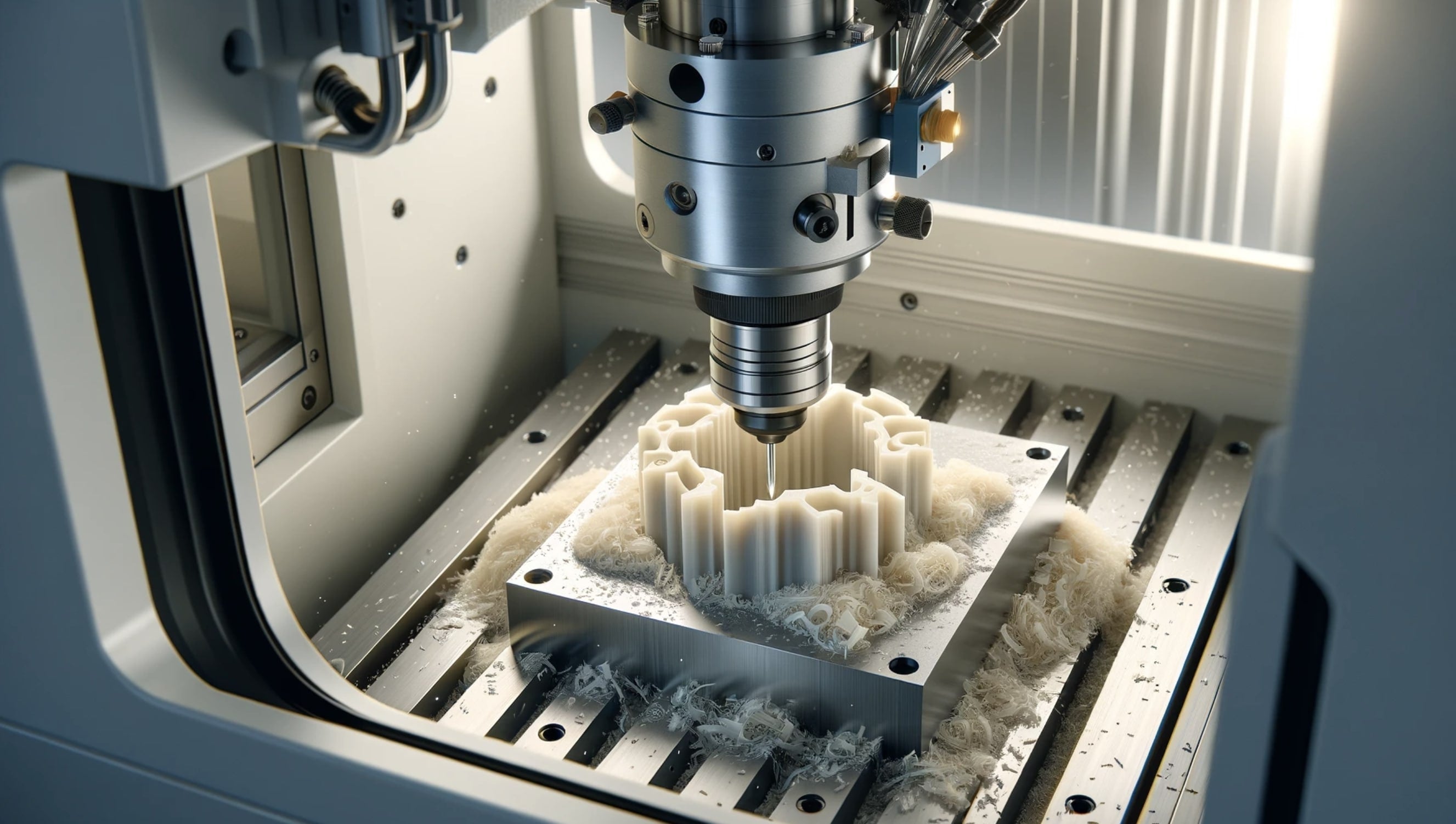

CNC (Computer Numerical Control) router machines play an essential role in the manufacturing landscape, providing the precise cutting, shaping, and engraving of various materials including wood, metal, and plastic, providing accuracy, efficiency, and versatility.

They automate the cutting and shaping of materials using pre-programmed computer software. Unlike traditional manual methods, they provide high accuracy and consistency, which is especially important when working with materials like plastics and metals.

How CNC Routing Works in 4 Stages

- Designing and Programming. The process starts by creating a 3D model of the part using CAD (Computer-Aided Design) software. This model is then turned into CNC code with CAM (Computer-Aided Manufacturing) software, which tells the CNC router how to cut the material. This step is important because it determines how precise and detailed the final product will be.

- Material Setup. Next, the raw material, like plastic sheets or metal rods, is securely placed on the CNC machine's table. It’s essential to align and fasten the material correctly for accurate cutting.

- Routing Operation. The CNC router uses the programmed paths to cut, engrave, or mill the material. Different tools and methods, like end milling and engraving, are applied depending on the design. This automated process allows for creating complex shapes with great accuracy.

- Finishing. After cutting, the part might be sanded or polished to improve its surface quality and meet precision standards. This final step ensures the product is ready for use or further assembly.

What is CNC Routing Used For

CNC routing is very effective for working with plastics, enabling precise cuts and complex shapes. Its automated process ensures accuracy and consistency, making it perfect for industries that need reliable production.

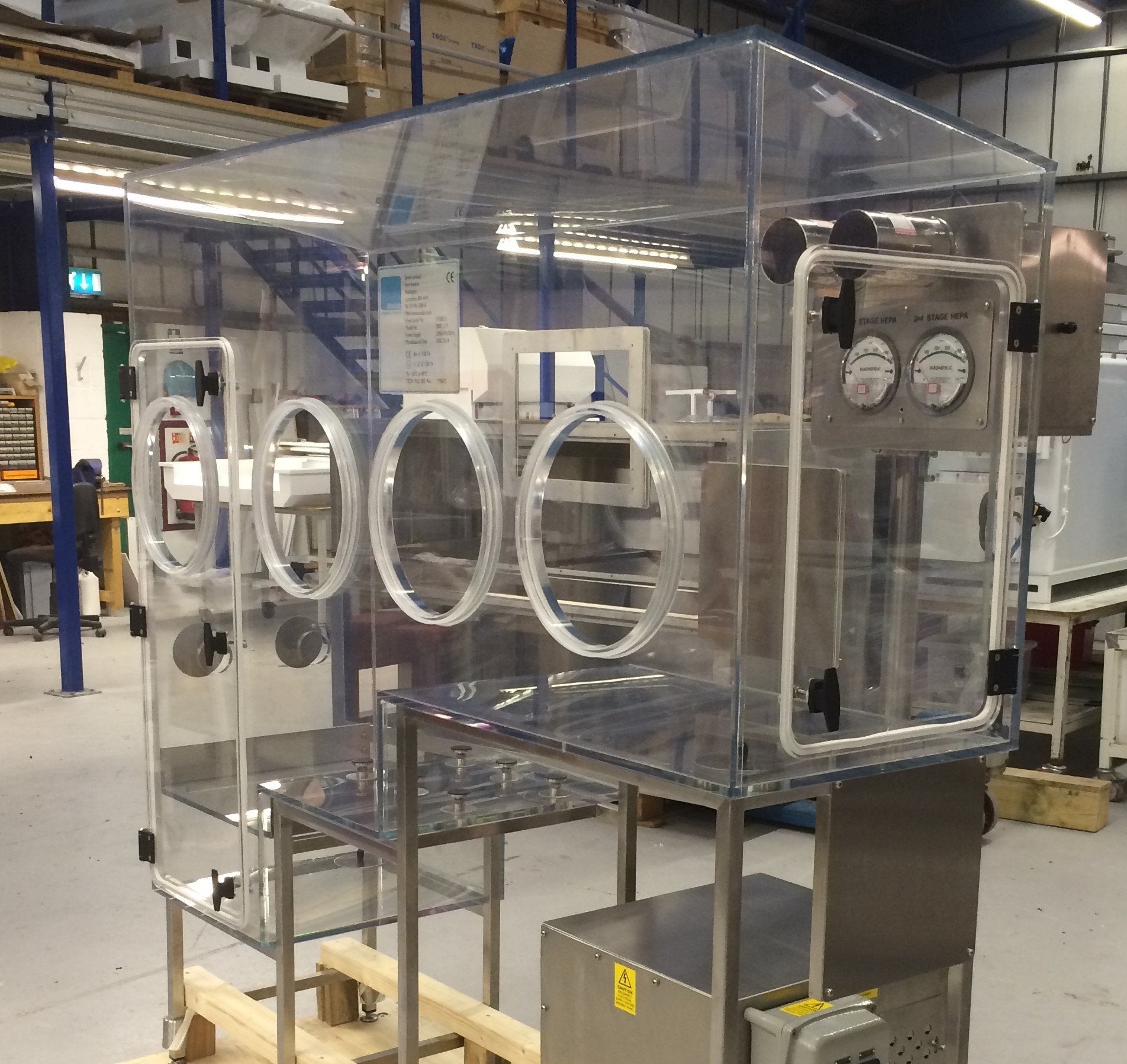

- Prototyping. CNC routing is great for quickly creating prototypes of plastic parts, allowing for fast design changes and testing.

- Manufacturing Components. It's commonly used in industries like automotive, aerospace, and electronics to produce components that require high precision.

Should You Use CNC Routing?

CNC routing is an efficient method for making parts in various shapes and sizes. By knowing the properties of materials, selecting the right tools, and fine-tuning cutting settings, manufacturers can produce high-quality results with less waste and lower costs. As technology improves, CNC routing evolves, opening up new opportunities for innovation and efficiency.

CNC routers are essential in modern manufacturing, providing precision, versatility, and efficiency. Whether working with wood, metal, or plastic, these machines allow for the creation of complex designs with minimal manual effort. By choosing a dependable brand and understanding the CNC routing process, manufacturers can boost their production capabilities and turn their creative ideas into reality.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.