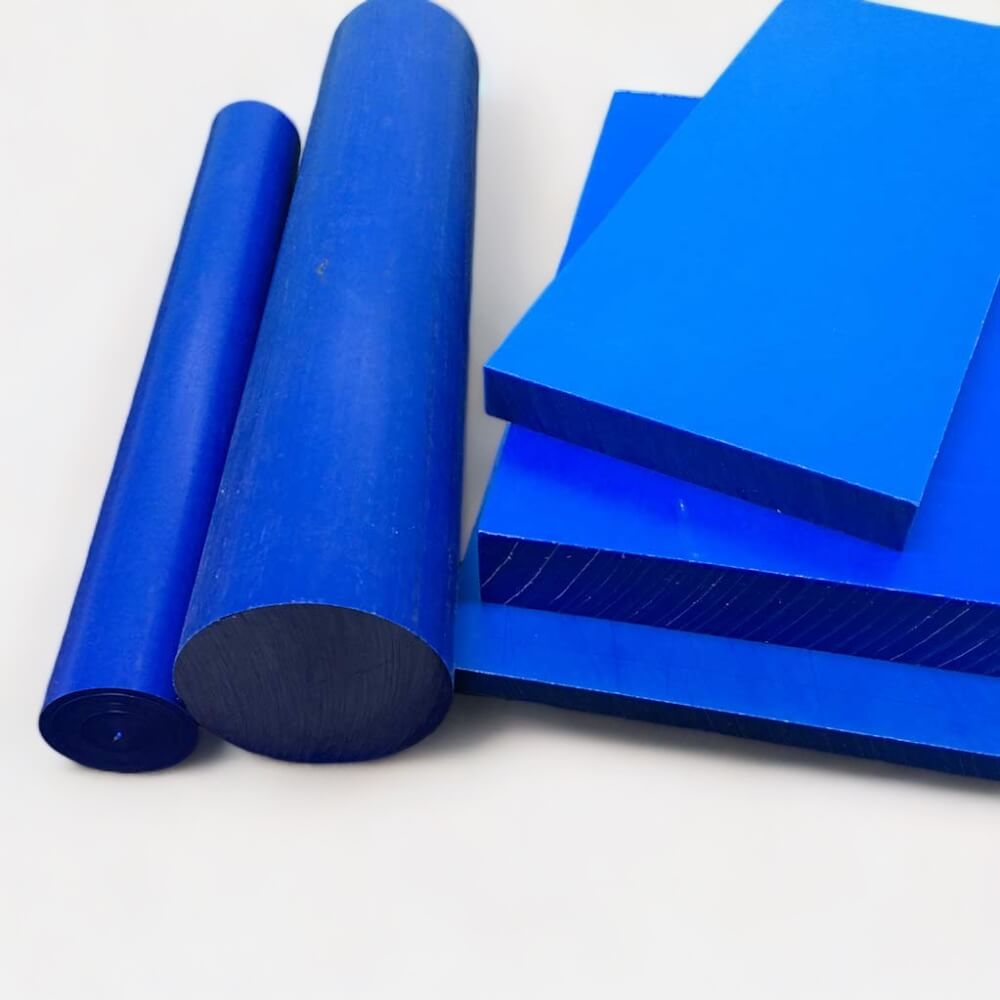

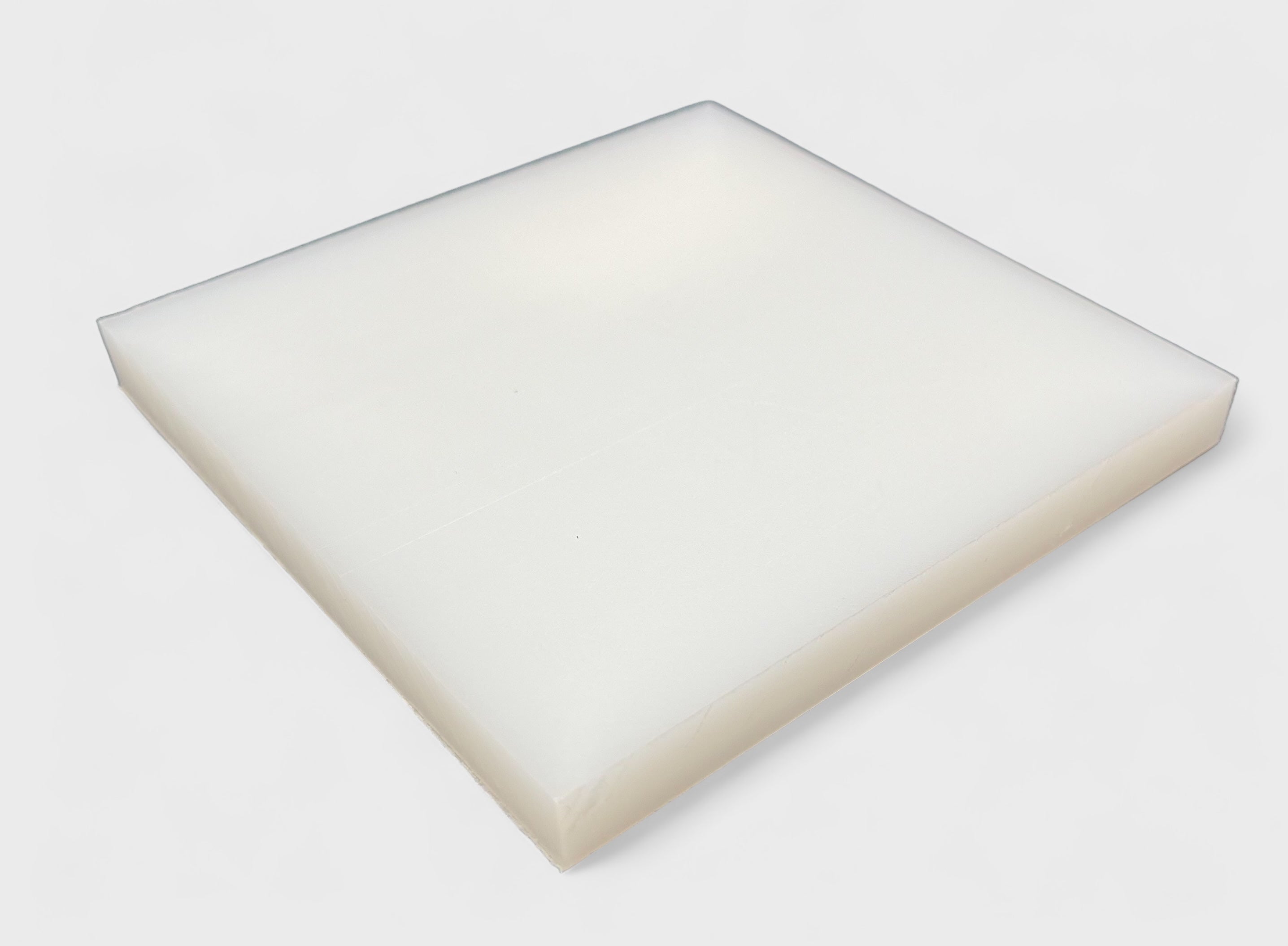

Delrin, also known as Polyoxymethylene (POM), is a high-performance engineering thermoplastic developed by DuPont. It is widely recognised for its excellent mechanical properties and versatility in various industrial applications. Here, we explore the key characteristics and uses of Delrin, demonstrating why it is a preferred material for precision parts requiring high stiffness, low friction, and excellent dimensional stability.

Key Characteristics of Delrin

- High Stiffness and Strength: Delrin boasts impressive mechanical strength and rigidity, making it an excellent choice for load-bearing applications. Its robust construction ensures reliability and durability, even in demanding conditions.

- Low Friction and Wear Resistance: With a low coefficient of friction and exceptional wear resistance, Delrin is ideal for moving parts. Its components show minimal wear, effectively extending the lifespan of various parts.

- Outstanding Dimensional Stability: Delrin maintains its shape and size across a broad range of temperatures and environments. This stability ensures consistent performance and precision, making it reliable in diverse applications.

- Good Chemical Resistance: Delrin is resistant to many solvents, fuels, and chemicals, adding to its durability in harsh environments. This resistance makes it suitable for applications exposed to various substances.

- Fatigue Resistance: Delrin withstands repeated stress and strain without significant degradation. Its fatigue resistance is key to its longevity and dependability in cyclic applications.

- Ease of Machining: Delrin can be machined to precise tolerances, making it ideal for producing complex and detailed parts. Its machinability supports the production of precision components efficiently.

Common Uses of Delrin

- Automotive Components: Delrin is used for gears, bushings, clips, and fuel system parts, where its high strength, wear resistance, and dimensional stability make it a top choice for these demanding automotive applications.

- Consumer Goods: Delrin enhances household appliances like zippers, fasteners, and gear wheels with its durability and low friction, improving product performance and extending their longevity.

- Industrial Applications: Delrin’s mechanical properties make it suitable for conveyor belts, bearings, and pump components in industrial settings, supporting efficient and reliable operation under demanding conditions.

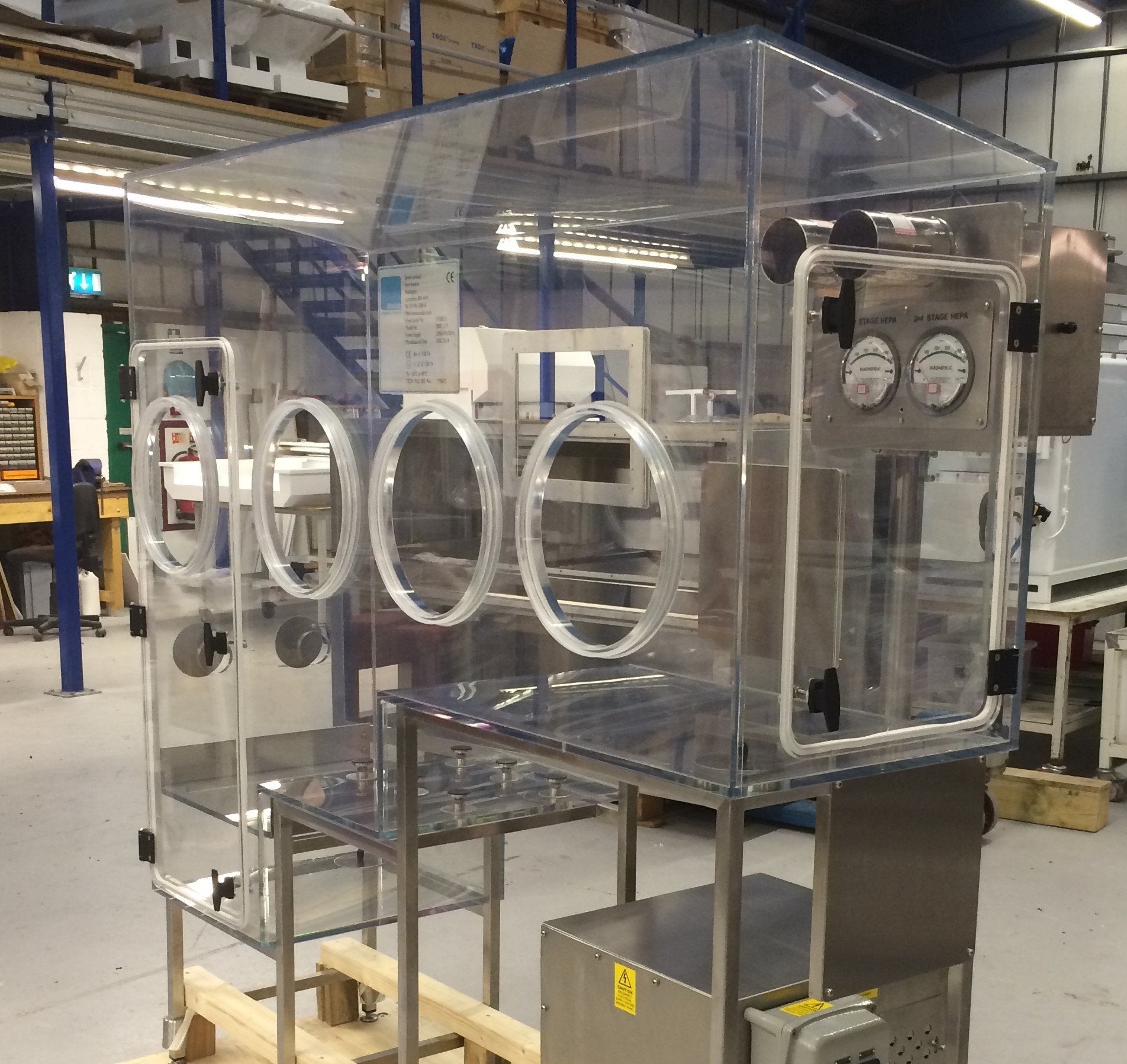

- Electrical and Electronics: Used in insulators, connectors, and various precision parts, Delrin’s dimensional stability and low friction are critical for applications in the electrical and electronics industry.

- Medical Devices: With its biocompatibility and ease of sterilisation, Delrin is used in diagnostic and surgical instrument parts. Its mechanical and chemical resistance properties make it a trusted material in medical applications.

Is Delrin Right for Your Needs?

Delrin possesses unique combination of high stiffness, low friction, dimensional stability, chemical resistance, fatigue resistance, and machinability makes it a preferred material for high-performance applications. Whether it’s automotive components, consumer goods, industrial equipment, electrical parts, or medical devices, Delrin continues to prove its versatility, reliability, and efficiency in precision engineering.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.